SPX FLOW Announces New APV Ball Valve Series

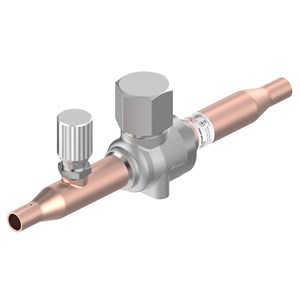

New APV Ball Valve Series (Image source: SPX FLOW, Inc.)

The new valves offer both durability and economy for a variety of applications in hygienic and non-hygienic applications.

The BLV1 Series share common parts with other APV valves across the portfolio, providing plants a common look, controls interface, and spare parts holding benefits with a multi-valve system. They are available with a simple manual handle with or without position feedback, as well as the same pneumatic actuators and a range of control units offered on the popular APV SV/SVS butterfly valve series. Advanced control unit options include the proven CU4 Series with ultra-bright LED position sensors and internal solenoids offering efficiency, clarity, and reliability at a competitive price.

Chris Sinutko, Global Product Manager at SPX FLOW, commented: “The addition of this ball valve range to our APV portfolio makes our offering more complete and provides customers with the convenience of a ‘one stop shop’ for all their valve needs. The BLV1 is a competitive, reliable, yet economical workhorse for a wide variety of applications.”

The BLV1 design is cavity filled with reinforced PTFE seats, stainless steel construction, and FDA approved food grade materials to provide hygienic performance. For utility service and other industrial chemical applications, the valves are designed with high temperature and pressure ratings and without the use of silicone. Other features include a wide range of both inch and metric sizes, full port opening for unrestricted flow in the open position, and lockable manual handle for added security.

Sinutko concluded: “The BLV1 series is provided based on our long expertise in hygienic and other industrial applications. Having common parts with other valve types from both the APV and Waukesha Cherry-Burrell range, customers not only have the convenience of dealing with a single supplier but also benefit from greater efficiency for maintenance operations.”

The BLV range is easy to install, service, and maintain with support from a global network of sales and service partners. SPX FLOW continually strives to assure service excellence and to provide the help customers need to keep their processes running and optimized.

Source: SPX FLOW, Inc.