Space-Saving Armstrong Pumps Ease the Way for Regent Street Refurb

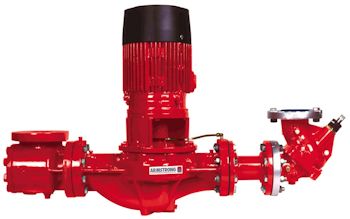

Pump design from Armstrong has provided a solution for space limitations at a prestigious refurbishment project in London’s Regent Street.

Armstrong

Quadrant, Regent Street, forms part of one of the most ambitious projects seen in the West End. It involves the conversion of the Grade II listed Regent Palace Hotel in Piccadilly, to create a mix of office, retail, residential and restaurant space around a central atrium. Originally built for J Lyons & Co in 1915, the hotel (with 1,000 rooms) was the largest hotel in Europe at the time. To keep aspects of its architectural heritage, three of the corner pavilions which make up the hotel’s original façade will be retained, and significant sections of the exquisite Art Deco interiors will be restored and reinstated.

When planning the new energy centre for the site, Construction Manager Sir Robert McAlpine and consultant AECOM were faced with space limitations. The amount of equipment which needed to be installed in the energy centre, to provide state-of-the-art building services for the site, was greater than the space available in which to house it.

There was a solution however. AECOM specified Armstrong 4300 Series vertical inline pumps fitted with space saving Suction Guides and Flo-Trex valves. These pump accessories reduce the physical footprint of the pump considerably, without impacting on the pump’s ability to meet building loads.

The Armstrong Suction Guide creates the optimum flow conditions at the pump inlet with a single component. This eradicates the need for the conventional Y Strainer, flanges, nuts, bolts, gaskets and suction spool piece. By cutting the number of components and connections in the system, the footprint and installation costs can be greatly reduced.

The Armstrong Flo-Trex combination valve provides similar space-saving features for the discharge outlet. It carries out the functions of a check valve, throttling valve and shut-off valve with just one component.

The reduction in physical footprint made possible by using these components in combination is considerable. For example, an Armstrong 4300 Series vertical in-line pump, fitted with a Suction Guide and Flo-Trex valve, may only require a third of the floor-space of a traditional base mounted end suction pump.

Tim Hare, Project Manager for Sir Robert McAlpine commented, “There was a lot of plant to fit into a small space. Armstrong was the company that could best ensure that we met that requirement. In addition, Armstrong has an established track record of successful projects for Sir Robert McAlpine, so we could feel confident of reliability and service levels.”

Source: Armstrong Fluid Technology