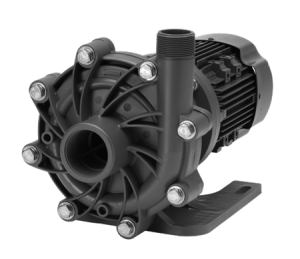

Siemens Expands Motor Portfolio for the Process Industry

The flameproof motors of the Siemens Simotics XP low-voltage motor series are now available across the entire power spectrum from 0.25 to 460 kW in gas groups IIB and IIC. (Image source: Siemens Aktiengesellschaft)

In addition, Siemens offers motors with Chemstar technology, which provide a tailored motor solution for the chemical industry with pre-configured, chemical-specific options.

According to explosion protection in zone 1 gas, the use of Simotics XP motors in the IIB version is possible. If hydrogen or acetylene are present, the IIC version is required. Both versions, IIB and IIC, are characterized by robustness, high availability, and a consistent platform concept. In addition, further options are available for the motors: Premium insulation enables speed-controlled operation with any converter with output voltages up to 690 V without any filter. Variants with reduced starting currents and the availability of the wide range of options with monitoring by PTC sensors (PTC thermistors) and PT100 (thermometers), with specific painting systems and modular attachments, such as speed encoders and brakes, complete the portfolio.

All common types of protection are covered by the consistent and integrated Simotics XP platform for explosion-proof motors and can be easily configured and adapted using the Drive Technology Configurator provided by Siemens. Simotics XP motors offer plant operators and machine builders a simple spare parts inventory, standardized tools, and ordering processes.

They run reliably and trouble-free under extreme operating conditions in aggressive atmospheres, both on the mains and on the frequency converters, and meet the requirements of the new, stricter EU Ecodesign Directive (ErP). From July 2021, the high energy efficiency class IE3 is also required for explosion-proof motors. The Simotics XP portfolio is available in energy efficiency class IE3 and in major parts also in energy efficiency class IE4. Motors with increased safety in the Ex eb version must meet energy efficiency class IE2 from July 1, 2023. IE3 is already standard for Simotics XP motors in the Ex eb version.

Chemstar concept – Tailord to the chemical and oil & gas industry

As a specific offering for the chemical and oil & gas industries, Siemens offers not only the explosion-proof motors of the Simotics XP series, but also motors of the Simotics SD series for environments without explosion hazard in the Chemstar version. They are equipped with pre-configured chemical-specific options, for example, fan shroud in steel plate, reinforced bearing, external grounding, IP66 protection, premium insulation system, VIK design and painting up to class CX according to ISO12977-2:2018 for the complete color spectrum including non-standard shades. Both motor series, available with options, operate reliably and energy-efficiently even under extreme conditions and offer all relevant certificates.

Source: Siemens Aktiengesellschaft