SEEPEX Smart Air Injection Video

A new video of SEEPEX’s patented sludge transport system and one of their many satisfied customers. (Image source: SEEPEX GmbH)

A new video of SEEPEX’s patented sludge transport system and one of their many satisfied customers. Watch the video here

Customized solution with two conveying technologies

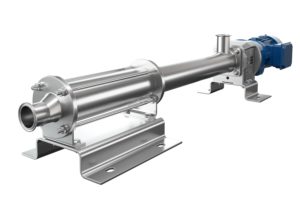

SAI is a customized solution that features the benefits of two conveying technologies: progressive cavity pumps and pneumatic dense phase conveying. It transports highly dewatered sludge over long distances – pipelines up to 1,000 meters in length – in an energy-efficient manner. Similar to an old pneumatic tube, the system compresses the sludge into plugs and conveys it to its final destination. For municipal water works, this alternative to conventional methods can pay off quickly. In other European countries, it has already proven very successful. More than 60 customers are benefiting from this innovation, which has a patent in Europe, the United States and China.

The Hetlingen WWTP turned to SEEPEX when it needed to improve its solids handling technology following a sludge dewatering upgrade. The solution had to be extremely flexible, as the existing plant is an intricate network of machines and pipelines. As shown in the video, this was no problem for the SEEPEX specialists. The company based in Bottrop, Germany, installed SAI as a complete system – pumps, compressors, sensors, actuators, the control system and all the pipework. The Head of Product Management, Dr. Stephan Mottyll along with Project Manager Christoph Jansen and Area Sales Manager Christian Rohmer supervised the project for SEEPEX. In the video, they focus on the special features of SAI for municipal water utilities, with on-site interviews and animations of the resource-efficient pumping technology.

Use less energy, minimize maintenance and eliminate odors

"A centrifuge dewaters the sewage sludge to a dry matter content of 23 - 25%, which then enters the hopper pump via a chute. The progressive cavity pump forms the typical SEEPEX plug and coats it with a lubricant to simplify its passage through the pipeline. Due to intermittent injections of compressed air, the slugs never completely fill the pipeline. SAI forms and then shoots small packages of the solid material through the system. Fluids provide further shear dilution," the SEEPEX experts conclude. According to Dr. Mottyll, the SEEPEX system is particularly efficient because it reduces pressure drops by a factor of 10 and it lowers energy consumption by up to 72%. The SAI technology is durable and requires little maintenance, while the reduced use of compressed air means less wear and tear. Additionally, SAI components are extremely easy to upkeep thanks to Maintain in Place features. In the case of rebuilds, SAI systems can also be adapted to new plant layouts. Another great advantage when transporting sewage sludge: The closed system with cleaning function ensures odor neutrality.

Energy savings improve energy balance

The Hetlingen WWTP serves over 40 cities and municipalities, and supplies over 500,000 people living close to Hamburg, Germany with water services. They treat approximately 31 million cubic meters of water per year. In the treatment process, the SEEPEX system conveys the sludge over a 30 meter vertical rise, followed by a 60 meter long elevated shaft to the loading silos. From there, the sludge is loaded directly onto truck beds and then transported to incinerators to be thermally recycled. The Hetlingen WWTP is pleased with the SEEPEX technology, according to project manager Stefan Holzwarth: "With SAI we are clearly reducing maintenance time, we need to intervene less during operation and the extra energy saved greatly benefits climate protection.

Watch the video here | Contact SEEPEX

Source: Seepex GmbH