Progressing Cavity Pumps From NOV Mono Chosen for Major New £300 Million Wastewater Facility

NOV Mono has provided ten progressing cavity pumps which are installed at the heart of a new wastewater treatment works in Sussex. The Southern Water works in Peacehaven features a number of different Mono pumps, including EZstrip cake pumps, LF injection pumps and Widethroat pumps.

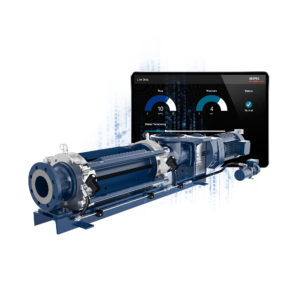

NOV Mono has provided ten progressing cavity pumps which are installed at the heart of a new Southern Water wastewater treatment works in Sussex. (Image: NOV Mono)

The new Peacehaven works is part of a £300 million environmental improvement that also includes 11 kilometers of newly constructed sewer tunnels, three new pumping stations and a new 2.5 kilometer outfall which has been constructed at nearby Friars Bay. “That creates a significant need for reliable and effective pumping solutions that will help keep the plant operating efficiently at all times,” says Mono Account Manager Mike Burton.

Mono worked with two of the sludge processing equipment providers involved in the project, the Andritz Group and Saxlund International, to offer the most efficient pumping solutions. “For Andritz, who supplied the plant’s sludge dewatering and drying equipment, we provided a variety of pumps which are now being used for different duties,” continues Mike. “These include transferring imported sludge cake, dosing dewatered sludge cake and boundary layer injection where lubricant is added to the pipework to ensure that the sludge moves smoothly through the system. Each of these is a key application in its own right, so reliable operation is absolutely crucial.”

Mono provided a similarly diverse package of pumps for Saxlund International who supplied the Sludge Cake Reception, Storage and Handling equipment for the plant, “These are now being used for cake blending, dryer feed, cake transfer and polymer dosing applications,” adds Mike.

“This project certainly demonstrates Mono’s ability to provide a really comprehensive package of pumps for large scale projects such as this one. The specific pumping requirements at the plant vary quite significantly from duty to duty, ranging from sludge transfer through to lubrication and dosing, yet the extensive range of products that we offer meant that we were able to meet all those requirements with ease.”

Many of the Mono pumps provided for Peacehaven feature the company’s innovative EZstrip technology, which has rapidly become accepted in the wastewater sector as a practical and highly effective way of reducing maintenance costs and improving uptime. The EZstrip design allows the cake pump to be dismantled simply by removing a few screws, and without disconnecting or removing any pipework. This gives immediate access to the rotating parts so that blockages can be removed quickly and easily, and can reduce the time taken to remove a full drive train, including rotor, stator and screw conveyor from a full day, down to just eight minutes.

“The EZstrip technology on the Mono pumps allows them to be maintained in place and that certainly offers attractive savings in terms of maintenance times and costs,” adds Matt Drew, Sales Manager for Saxlund. “Having such a wide variety of pumps supplied by a single manufacturer was also an attractive proposition as it helped ensure compatibility between various parts of the process.”

The completed Peacehaven wastewater treatment works is covered by an 18,000m² grass roof – one of the largest green roof of its kind in Europe – and handles the 95 million litres of wastewater which is generated each day by residents of Peacehaven, Telscombe, Saltdean, Rottingdean, Ovingdean and Brighton and Hove.