Power Plants Will Spend $8 Billion for Valves In 2016

Power plant valve purchases will remain at a high level thanks to continued construction of new coal-fired power plants in China, Vietnam, Indonesia and Japan. Despite the fact that Japan was the host of the original greenhouse gas reduction convention (Kyoto Protocol), the country is planning 40 new coal-fired power plants.

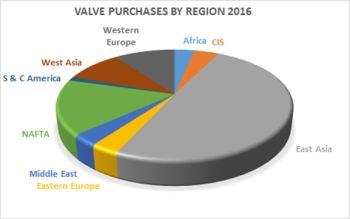

Valve Purchase By Region 2016 (Foto: McIlvaine Company)

Old coal-fired power plants will be retired, so CO2 emissions will not be increased. The EU also is building new coal-fired power plants to replace higher emitting old power plants. In Asia, the need for new electricity and the lack of natural gas are the big drivers.

Next year nearly 50 percent of the $8 billion power plant valve expenditures will be by East Asian power generators. NAFTA will be the second largest region thanks to construction of new gas turbine combined cycle power plants. These forecasts are provided in Industrial Valves: World Market.

Coal-fired power plants are at the top of the list with regard to valve opportunities. The reasons are twofold. First, more coal-fired power plants will be built than thermal power plants. Second, coal-fired power requires water management in both the liquid and steam phases, as well as various slurries for flyash, bottom ash, and limestone for flue gas treatment. Additionally, there are valves required for the many chemical systems to treat boiler feedwater and plant wastewater. Valve types include pressure relief valves, as well as globe, gate, ball, butterfly, plug and check valves. It is estimated that a typical utility-scale coal-fired power plant includes more than 5,000 valves.

Nuclear power is second on the list, with a slightly smaller number of valves per plant because there is no requirement for flue gas treatment or flyash and bottom ash handling. Nevertheless, the redundant systems in nuclear power plants ensure a large number of valves on par with coal-fired power. There are currently 60 nuclear reactors under construction in 13 countries.

Gas-fired power plants hold significant potential for valve sales both in terms of numbers of new plants, and in terms of plant complexity. Most gas-fired power plants currently being built reflect a combined cycle design that includes a gas turbine, as well as a Heat Recovery Steam Generator (HRSG) with the attendant valves for boiler feedwater, condensate, cooling water, and water treatment chemicals. These plants operate with efficiencies of greater than 60 percent, and are now sized 400 MW and larger for baseload power generation as well as for backup power for intermittent renewable energy.

Source: The McIlvaine Company