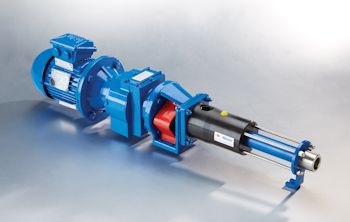

NOV Mono Provides a New Pumping Solution for Dosing/Metering Applications

A new range of dosing pumps launched by NOV Mono offers an efficient, reliable and low maintenance solution for applications where low flow, accurate dosing is required.

The new Mono dosing pump provides a smooth pumping action with no pulsation and very low shear. The pump is ideal for either intermittent or continuous dosing duties in high pressure, low flow applications, and represents a cost-effective and reliable alternative to the more expensive gear pumps traditionally used for these types of duties.

The new dosing pump offers many advantages, not least of which is the option to transfer low flows at high pressure (up to 72 bar/1044 psi). With no valve components (reducing the number of wearing parts), blockages are eliminated and the working pump life is extended. Stators are available in a variety of different materials, and their flexible and resilient operating characteristics enable the pump to handle a wide variety of applications, and again, increase the pump’s resistance to wear. When maintenance is required, it can be completed without the need for any specialist skills, thereby maximising uptime.

Manufactured to ISO 9001:2008 quality assurance standards, the modular design of the new dosing pump allows the four models in the range to cover performance requirements from 25 litres per hour (0.11 USGPM) and 72 bar pressure (1044 psi), up to 1,250 litres per hour (5.5 USGPM) and 12 bar pressure (174 psi). All the pump components, with the exception of the body, coupling rod and suction chamber are supplied in stainless steel as standard, and have the option for internal pump components to be supplied in Hastelloy, which allows the pumps to be used in severe chemical environments. Other optional features include a range of fixed or variable speed drives with mechanical variable speed or a frequency inverter.

“This pump builds on the success that our Compact C range has enjoyed to date,” says Mono’s European Sales Manager, Ian Horton. “The pump also shares a number of components with the small Compact C pumps, which reduces the need for stockholding and provides extra flexibility for interchangeability of parts. Together with high reliability and low maintenance requirements, the new dosing pump delivers many benefits for dosing or metering applications.”

Picture: A new range of dosing pumps launched by Mono offers an efficient, reliable and low maintenance solution for applications where low flow, accurate dosing is required. They represent a cost-effective and reliable alternative to the more expensive gear pumps traditionally used for these types of duties.(Image: Mono Pumps)