Lower Operating Costs by 75%

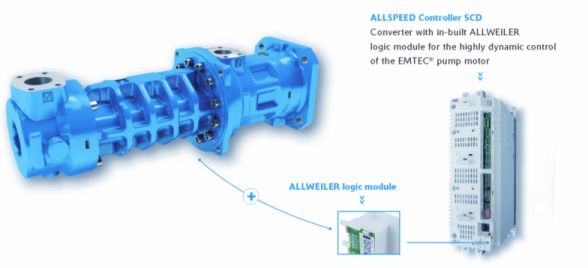

Allweiler AG has developed a new system for regulating the speed of its screw pumps. "Allspeed" is a control system that forgoes the use of valves. It enables use of smaller pumps with a smaller motor.

Standard cage rotor motors may be used without external ventilation. Allspeed augments the Emtec series, which is designed specifically for pumping coolants in tool machines.

The core element of Allspeed is Allweiler s proprietary control algorithm. It adaptively controls the associated frequency converter in real-time so the pump can adjust to changing conditions at individual tools in less than 500 ms. With the system, speed jumps of up to 5,000 1/min. and pressure differentials of up to 120 bar are no problem. In addition, the pump has the ability to approach the tools individual operating points directly and with high precision. It will not overshoot or continuously readjust on both sides of the target pressure. Thanks to its incredibly fast reaction time, the pump will also stop running as soon as the demand for coolant has stopped. As a result, standby losses and standby expenses approach zero. Allspeed also monitors motor temperature and other key values. The system automatically adjusts the flow rate and emits warnings when key values enter a threshold range.

Use of Allspeed in conjunction with Emtec pumps significantly lowers power costs and results in additional financial benefits. As an all-around plug-and-play system without expenses for programming and parameterizing, one pump size is able to handle a very wide range of pressures and capacities. In addition, operators can now use low-pulsation screw pumps instead of the more common centrifugal pumps up to 25 bar. Grinding applications are a prime example. Energy savings can be as high as 75%. In addition, maintenance intervals of the pump, controller, and piping are greatly extended. Allspeed replaces the valves of conventional systems, thereby eliminating wearing parts. Low-pulsation pumping is also more gentle on the entire installation. In general, the pump is subject to less loads because it operates for shorter periods of time and at a lower average speed.

Allweiler board member and Colfax Senior Vice-President for Europe, Middle East, Africa, and Asia, Arne Forslund describes it this way: "The new Allspeed controller significantly lowers the operator s TCO (Total Cost of Ownership) while simultaneously elevating operational safety." The control algorithm and its application for controlling displacement pumps has been registered for patent protection.

Source: ALLWEILER GmbH