LEWA realizes heads of 90 meters with DIN EN ISO 2858-compliant NIKKISO canned motor pumps

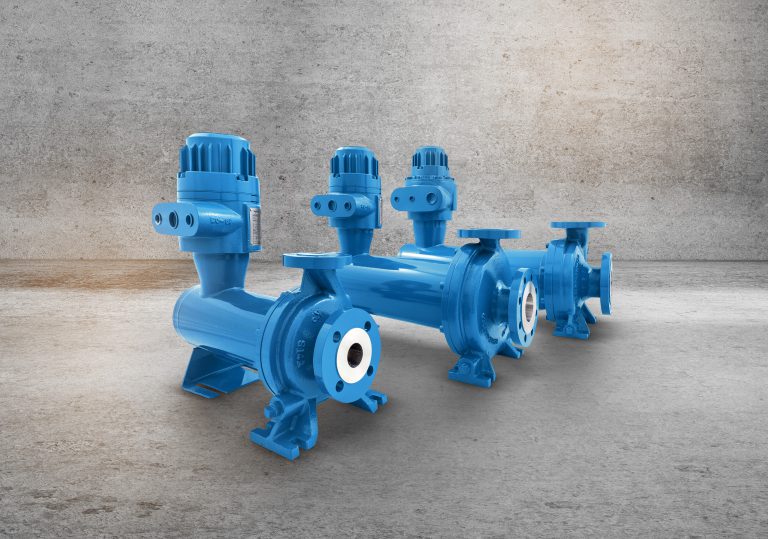

The last four of a total of twelve different pump sizes of NIKKISO canned motor pumps designed according to DIN EN ISO 2858 have been available since April 2020. (Image source: LEWA GmbH)

These robust units are required in the chemical and petrochemical industry in particular. In response, German pump specialist LEWA has successively expanded its portfolio to include various models of the proven Non-Seal canned motor pumps from Japanese parent company NIKKISO Co. Ltd. The last four of a total of twelve different pump sizes designed according to DIN EN ISO 2858 have been available since April 2020.

With the DIN EN ISO 2858 models 50-32-160, 50-32-200, 50-32-250 and 65-40-250, NIKKISO completed its range of canned motor pumps for chemical and petrochemical transfer tasks for the European market in April 2020. All pumps in the series offer a safe, reliable alternative to standard centrifugal pumps due to their compact, robust design and low-vibration operation. With the market launch of the four new pump sizes, heads of up to 90 m are now possible. The maximum flow rate is up to 80 m³/h. Fluids in a temperature range from -60 °C to +400 °C can be pumped without difficulties. In addition to conforming to the European standard for standardization of centrifugal pumps, all ISO models are certified according to the ATEX 2014/34/EU directive for use in potentially explosive working environments. LEWA also offers NIKKISO Non-Seal pumps in customized versions, for example in API 685-compliant design for use in the petrochemical industry.

Source: LEWA GmbH