LEWA ecoflow LDG Process Pump Is Now 15% More Powerful within the Same Footprint

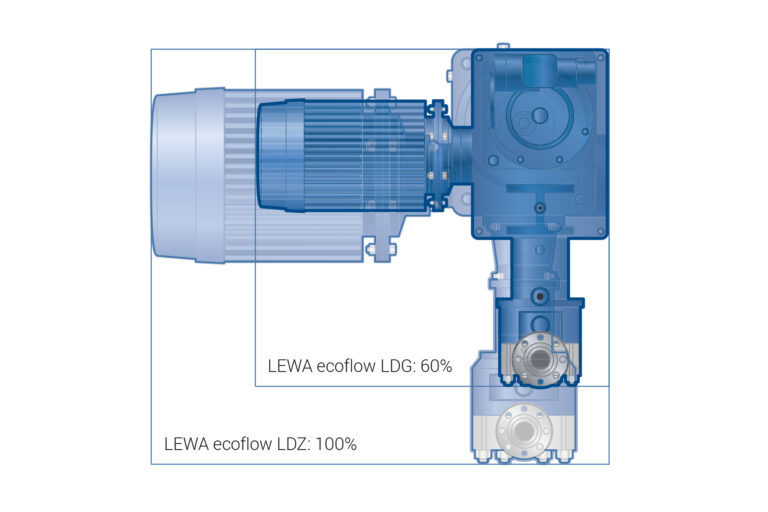

Improving the performance of the LEWA ecoflow® LDG pump can save up to 40% space compared to the larger LDZ model. (Image source: LEWA GmbH)

For example, applying the improved ecoflow LDG at a flow rate of 300 l/h increases the maximum discharge pressure from 659 bar to 713 bar. Conversely, at 100 bar discharge pressure the maximum flow rate increases from 2600 l/h to 2950 l/h.

Nicoline Walther, Product Manager for the LEWA ecoflow product range, says: “Optimising productivity in processing applications is a constant challenge. It requires the right combination of pressure and flow rate, and space is always at a premium. Enhancing the power-to-footprint ratio of our ecoflow LDG pump enables customers to specify a smaller unit and achieve higher performance. Compared to the next pump size in the ecoflow range, the LDG can reduce space requirements by up to 40%.”

Reinforcing LEWA's commitment to continuous innovation, the upgraded ecoflow LDG represents a power increase from 35kN to 40kN. This innovative approach is aligned with the improvements made last year to its larger sister pump, the LEWA ecoflow LDZ, which raised power output from 45kN to 50kN and improved its performance by 10%.

The LDG is part of the LEWA ecoflow family, an extensive modular system of diaphragm and packed plunger metering pumps that combines eight drive sizes with six different pump heads. This modular design allows for a high degree of customisation. Further options include different materials and valve types that can be combined to meet specific application criteria including temperature, compressibility, flow rate and pressure. The ecoflow can handle aggressive, abrasive, toxic, and flammable fluids to meet diverse applications in the energy sector, chemical production, pharma, and food and beverage.

Renowned for leak tightness, operational safety and reliability, LEWA ecoflow pumps provide highest metering accuracy, even at high pressures. Their precise and reproducible flow rate can be adapted via stroke length and speed, offering a broad metering range of 1:100 for flexible adjustment to different tasks.

Like all ecoflow pumps, the LDG is backed by LEWA’s global spare parts and service availability, which ensures customers have total lifecycle support that guarantees maximum availability and a long service life.

Nicoline Walther concludes: “The ecoflow LDG is one example of how we are constantly refining and improving our product range. But achieving excellence is not just about great technology. We support our customers from planning and commissioning to maintenance, repair and upgrading to ensure that our metering and process pumps consistently meet the application’s requirements and deliver the desired outcomes as efficiently and cost-effectively as possible.”

Source: LEWA GmbH