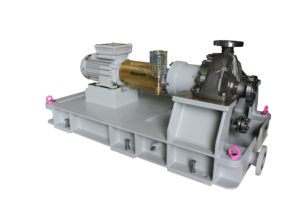

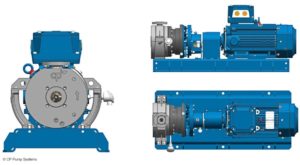

High-Efficiency Uniquely Engineered Magnetic Drive Pump

Iwaki America Inc. offers a premier line of non-metallic centrifugal pumps with unique features. Expertly engineered with a unique internal cooling circuit, double-bearing system and inner rotating assembly, the WMD and MD line of Iwaki pumps provide high efficiencies and improve the life-cycle costes of any system.

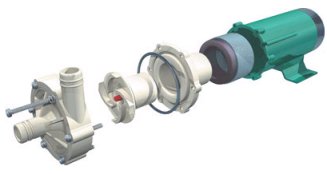

The unique internal cooling circuit uses a hollow rotating spindle which creates a positive, forced cooling path, lubricating bearing surfaces and providing a low pressure escape to the eye of the impeller through the hollow spindle. The unique double bearing system allows the cooling circuit liquid to continually wash front and rear radial bearings, extending bearing life.

The inner rotating assembly of alumina ceramic or SiC spindles are bored, turned and highly polished and form the center of the driven rotating assembly. Balance holes traditionally employed only in large process pumps are expertly engineered into the impellers of the WMD and MD pumps. Radial bearings of high lubricity fluoropolymer minimize mechanical losses typical of conventional mag drive pumps. Available high purity SiC radial bearings handle the most aggressive or ultrapure chemistries. The WMD and MD line offers maximum flows to 35.6 and maximum head of 67 feet.

These highly efficient pumps are compact, offer higher pressure and longer life than traditional offerings. They are well-suited for laser, chiller and blood analyzer applications as well as any process, re-circulation or transfer application. They can handle both aggressive or high purity requirements.

Source: Iwaki America Inc.