HI & PSM Debut Latest Training Webinar Series On Power Plant Pumps

The Hydraulic Institute (HI) and Pump Systems Matter (PSM) will unveil their latest educational training event, Power Plant Pumps - Maximize your Uptime & Reliability: 3-Part Webinar Series, on February 20, 2014.

The series will continue with the second and third session respectively on February 27th and March 6th. Webinar participants will be led by and have access to Power Generation Expert, William Livoti, Business Development Manager Power Generation, WEG Electric Corporation. Registered participants earn three (3) professional development hour (PDH) credits for attending the series as well.

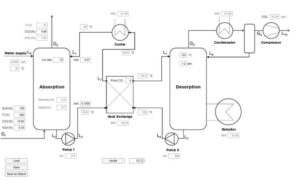

This series will cover major changes in the power industry and help engineers better understand how pump selection may affect the overall design and reliability of their power plant. In addition to increased demand for electricity, new government legislation is imposing more stringent emission controls on coal-fired power plants (CFPP) and the amount of CO2 they can produce. Even as existing CFPPs retire due to the inability to comply with new restrictions, very few new plants are being approved for construction to replace them. As a result, remaining power plants must operate more efficiently to address increased demand; power plant efficiency/heat rate, therefore, becomes an issue. One way to achieve higher efficiency, improve uptime, availability and reliability while reducing heat rates is to optimize motor-driven pump systems within these plants.

Session 1 will cover the state of the power industry, configurations, and combined-cycle plants. Session 2 will discuss specific processes and pump selection and the final session will cover existing systems and troubleshooting. More specifically, this series will:

- Describe basic operation of combined-cycle plants and the importance of uptime, reliability and availability.

- Identify pump designs used in typical combined-cycle power plants and recommend how to operate them at highest efficiency and reliability.

- Offer recommendations on specific processes based on plant operation including start-up and shut-down procedures and off-design performance. Any change in plant operation affects the pumping system.

- Review types of pump used for different plant processes, applicable industry standards and best practices, critical features and operating parameters of pump design and any special features or characteristics relative to specific pumps.

- Recommend and describe the type of fluids each pump design typically handles and their critical properties (pressure, temperature, corrosiveness, toxicity, abrasiveness, pH).

- Discuss construction materials for main service pumps, pump seals and packing recommendations as well as lubrication systems available for pumps and pump sets.

Advance registration is required and HI members and standards partners receive a 25% discount off the regular registration fee for the series. Upon registration, participants will receive a 20% off promo code to use towards the purchase of the recently published guide, Power Plant Pumps: Guidelines for Application & Operation in their confirmation email. This guide is a great companion for all webinar participants.

To register, visit the Power Plant Pumps registration page in the HI eStore.

Source: Hydraulic Institute Inc.