Gentle on Resources and Digitally Networked: the next Generation of Glass Fillers from KHS

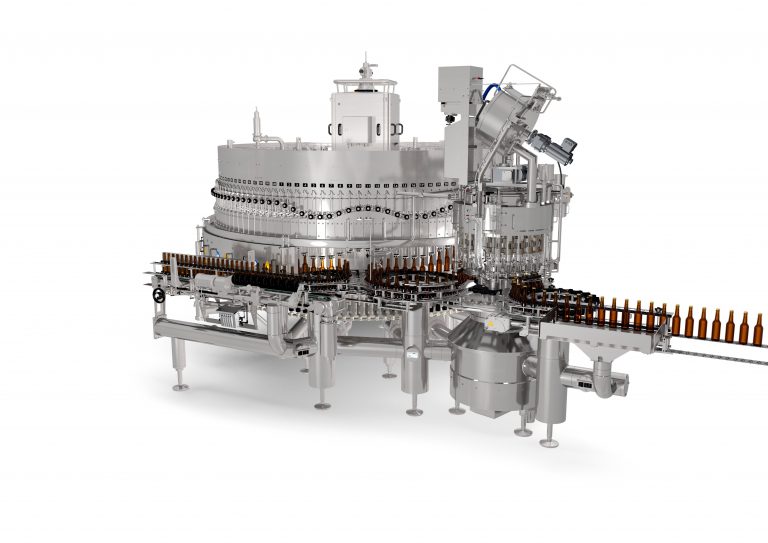

The Innofill Glass DRS ECO combines the tried-and-tested KHS filling system with digital, resource-saving technologies. The glass filler thus scores on both efficiency and sustainability. (Image source: KHS GmbH)

At BrauBeviale the systems supplier will be presenting the glass bottler in what is known as its ECO variant to the public for the first time.

The DRS ECO is distinguished by its lower energy consumption (which is reduced by up to 20 percent), with CO2 emissions even falling by as much as 50 percent. Thanks to digital networking and monitoring the glass bottle filler also provides optimum product quality and increased line availability.

“Many bottlers are expanding their portfolios at the moment. We’re seeing an increased demand for glass containers in particular,” says Manfred Härtel, filling product manager for KHS. “With the Innofill Glass DRS ECO we provide pioneering filling technology which meets the growing market requirements for flexible and efficient production processes,” he continues. The new KHS system bottles beer, mixed beer beverages, cider and soft drinks. It can easily fill containers holding between 0.1 and 1.5 liters, processing up to 80,000 0.33-liter bottles an hour, for instance.

In addition to being flexible and efficient, the DRS ECO is also convincing when it comes to sustainability. The new filler is thus called because it makes use of KHS’ unique ECO system, a special evacuation and CO2 purging process for glass bottles. With this it consumes up to 50 percent less CO2 compared to conventional methods. KHS has also cut the amount of energy used by a maximum of 20 percent thanks to its optimized vacuum pump.

Automation for optimized filling and sanitizing processes

The KHS glass filler also boasts a number of intelligent digitalization and automation technologies. The DIAS diagnostic assistance system, for example, monitors the entire filling process. “There are pressure sensors installed in every single filling valve which continuously detect any deviations from target values or bottle breakages,” explains Härtel. The evacuation and CO2 purging processes especially are monitored to ensure the lowest possible oxygen pickup. DIAS recognizes broken bottles in all filling phases and triggers the bottle burst routine fully automatically. KHS’ SOFTSTOP bottle flowgate is also of great importance when it comes to product protection. It interrupts the flow of bottles gently and quietly, even at maximum speed, for a very homogenous filling process and constant foaming quality. Oxygen pickup is kept at a very low level.

The camera-controlled high-pressure injection control system called OPTICAM enables the head of foam to be monitored and regulated fully automatically, cutting product loss by up to 50 percent. The new fill level probe on the Innofill Glass DRS also ensures optimum filling results. It not only measures the fill level but also monitors the CIP process. The glass bottle filler can also be fitted with fully automatic CIP caps. These shorten changeover times and lower the amount of cleaning media used.

The hygienic QUICKLOCK fast-acting locking system makes for trouble-free format part changeovers, with bottle guide parts exchanged with just a few manual adjustments performed without tools. This reduces conversion times by up to 30 percent to just 15 to 20 minutes.

Standardized basic structure for great flexibility

With its new generation of fillers KHS is pushing ahead with a project which is to prove groundbreaking for the system supplier’s entire product spectrum. “We plan to give all our fillers the same modular machine structure and as many identical parts as possible in the future,” Härtel states. This means that our customers can quickly and flexibly retrofit their base machines with additional components – depending on how the beverage market and their own production policies develop. This gives them greater security for the future.”

Source: KHS GmbH