Franklin Electric’s SubDrive Connect Now Available With Surface Pump Functionality

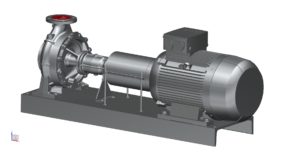

Franklin Electric announces that its proven SubDrive Connect product family of variable frequency drives now offers the addition of surface pump functionality for residential, commercial, small municipal, and irrigation applications.

This is a standard product upgrade that provides basic and advanced setup via either DIP switches or the FE Connect mobile app to achieve constant water pressure from compatible 230 V three-phase surface pumps with an overload current rating from 2.0 A to 17.8 A – including the Franklin Electric VR Series, MH Series, BT4 Series, and DDS Series pumps. Basic DIP switch settings allow for easy setup of overload current, system response, and a lower minimum frequency setting, whereas advanced settings using FE Connect allow for a customized system response and fine tuning of motor overload current, frequency range, and pump priming delay. In addition to typical applications, SubDrive Connect is easily programmable and an ideal solution for duplex pumping applications with submersible pumps, surface pumps, or a mixture of the two.

SubDrive Connect variable frequency drives continue to include the same features and functionality with surface pumps as they do with submersible pumps. The standard Enhanced Features package includes an analog pressure transducer with user selectable set point, moisture (or wet floor) sensor, and system run and fault relays. Utilizing the innovative FE Connect, contractors also benefit from the advantages of drawdown, an auxiliary control input, and the built-in duplex alternator. The end result is a drive platform that optimizes system performance, delivers more precise pressure and system diagnostics on screen, simplifies lead-lag installation, and provides contractor peace of mind.

The SubDrive Connect family features a NEMA 3R (Type 3) enclosure rated for both indoor and outdoor use, providing a degree of protection against falling rain or sleet. FE Connect is a convenient way to set up and configure the drive and, once configured, it allows real-time monitoring of key system data, adjustment of advanced features and settings to optimize the system to the specific application, and access to fault history – up to 500 detailed entries that can be emailed for enhanced troubleshooting capability.

Source: Franklin Electric Co., Inc.