Chemineer ChemSeal Specifically Designed for Agitator Service

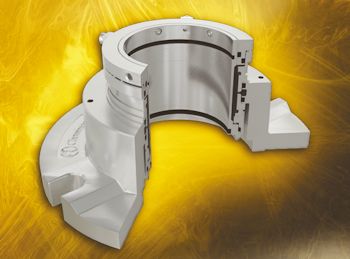

The ChemSeal is designed specifically for agitator service. ChemSeal is a true agitator seal featuring high runout, reverse rotation and reverse pressure capability.

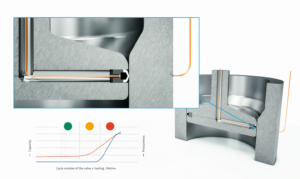

The ChemSeal line features both single and double cartridge configurations designed for easy installation and maintenance. The ChemSeal cartridge seals can be readily removed from the agitator as a complete assembly and quickly repaired on the workbench before re-installation, saving maintenance time and effort. Chemineer’s "swing-out" agitator seal change design contributes to the ease and the speed of seal replacement, helping to reduce maintenance costs.

ChemSeals are available in a variety of materials to meet critical temperature and pressure ratings, satisfying a broad range of mixing/agitation applications. The ChemSeal can be easily retrofitted to existing Chemineer GT, Model 20, and MR agitators to provide improved sealing capability on existing applications.

Optional throttle bushing or debris well designs are available to prevent seal and product contamination. Dry and liquid lubrication options are also available to suit specific application requirements.

ChemSeal design features include:

- Double balanced inboard faces for optimal performance

- Setting clips for easy installation

- Reverse pressure capability which keeps seal faces closed when tank pressure exceeds seal pressure

- Bi-directional rotation capabilities

- Modular components for economical application flexibility

- Quench and drain ports for easy lubrication

- No seal adapter required

- Standard sizes in 2”, 2.5”, 3” and 3.5”

- Temperatures to 356°F (180°C)

- Pressures to 300 psi

ChemSeals are fully supported by the Chemineer Express program for off the shelf delivery of standard seals. Refurbishment/repair programs are available as well through Chemineer Express.

Picture: Chemineer® Double Mechanical ChemSeal (Image: Chemineer)

Source: NOV, Inc.