Allweiler Invests in New Stator Production Site

Allweiler modernized its stator production facilities to make them more environmentally friendly and energy efficient. The plant was acquired from the New-York Hamburger Gummi-Waaren Compagnie in March 2005. Since then, Allweiler has been producing all stators for its progressing cavity pumps there.

The company earned a subsidy from the Hamburg-based promotional program Unternehmen für Ressourcenschutz (“Companies for Resource Protection”) for this investment.

For the environmental and energy-saving measures alone, the Hamburg production site expended more than 162,000 euro. Allweiler modernized several of the machines used to produce stators for progressing cavity pumps. Other systems like the vulcanization pan were replaced in their entirety. The new power supply and the new cooling system together have lowered energy consumption by nearly three million kilowatt hours per year at the same level of production. Carbon dioxide emissions have decreased by 550 metric tons per year.

The core of the modernization efforts are the new, highly insulated vulcanization, pre-warming, and cooling pans with temperature control, a secondary loop with heat exchanger, and a filtering unit. Improved insulation and control alone account for energy savings of 921,000 kilowatt hours per year. “With these new facilities we can deliver the highest quality stators in 19 different materials in the shortest time possible,” explains Klaus Stahlmann, CEO and Chairman of the Executive Board.

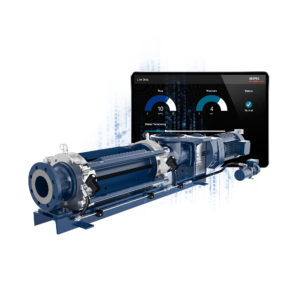

Stators are an important part of progressing cavity pumps manufactured by Allweiler AG. Clarification plants, the food and beverage industry, and chemical manufacturers around the world order about 10,000 of these pumps every year. Depending on the pumping task and the liquid being moved, stators may be constructed of a variety of materials so the pumps stay in service as long as possible without exhibiting wear or needing maintenance. Only very few pump manufacturers can assure their customers and users that their products contain stators from their own production. In most cases, stators are procured from external suppliers who work for several different pump manufacturers. Manufacturers need special machines and knowledge to process elastomers properly.

Founded in 1860, Allweiler AG is the oldest German pump manufacturer and the European market and technology leader for centrifugal, propeller, screw, eccentric spiral, rotary lobe, gear, macerator, and peristaltic pumps. Allweiler AG owns a foundry and also produces ready-to-use pump skids. Allweiler AG has their main German headquarters in Radolfzell on Lake Constance as well as a major subsidiary in Bottrop, Germany. Allweiler AG has been part of the Colfax Corporation since 1998.

Source: ALLWEILER GmbH