Larger Dispensing Volume with the Same Size

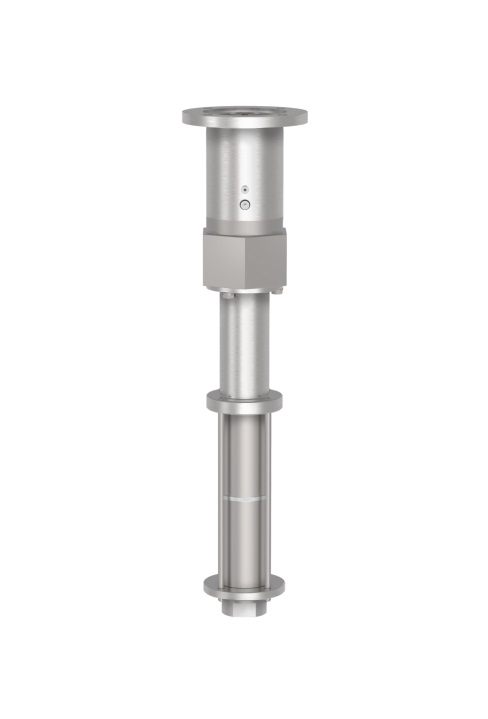

From the outside, the 2VMP22-3D does not differ from the 3VMP22. (Image source: ViscoTec Pumpen- u. Dosiertechnik GmbH)

The 2VMP22-3D facilitates the dispensing of single-component fluids and pastes in larger quantities. Compared to existing dispensing pumps of the VMP series in the ViscoTec portfolio, the 2VMP22-3D impresses with its larger dispensing capacity due to 3D geometry with the same frame size: > 5 liters per minute.

Another advantage are different elastomers for the stators, which can be selected to suit the respective application. This makes the 2VMP22-3D suitable for applications with particularly abrasive or chemically aggressive materials.

A separable rotor assembly simplifies the disassembly of bearings and seals. This means that in the event of wear on the drive shaft or seals, it is no longer necessary to replace the entire rotor assembly, but only the drive shaft assembly. The rest can be reused. This means that customers whose main wear parts are seals and drive shafts can avoid approximately 50 % of the costs.

Advantages of the VMP dispensing pump series:

- Volumetric dispensing, regardless of viscosity

- For low to high viscosity fluids

- For shear-sensitive, filled, abrasive materials

- Continuous dispensing, pulsation-free

- Inner housing non-stick coated

- Linear dependency on application quantity and speed

- Programmable suck-back prevents dripping or stringing

- Long service life due to low wear

- Easy cleaning and maintenance due to quick assembly and disassembly

The 2VMP22-3D can be perfectly integrated into barrel emptying or material treatment systems – especially for containers with 20 to 200 liters. Previously, this required very large and heavy systems. However, it is also equally suitable for various dispensing applications as a stand-alone dispensing pump for single-component materials.