Vesconite Hitemp 150 Without a Scratch for One Year

A canister pump - the type of pump that ensures that golf courses are green and lush. (Image source: Vesconite Bearings)

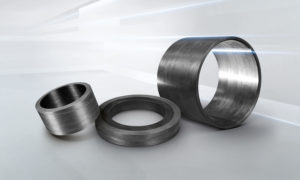

Kyle Pienaar, of Golf Turf Electronics, found that the OEM-supplied carbon pump bowl bushings lasted only two months at the Sabi River Sun course, while another polymer’s bushings lasted six months in the highly-abrasive debris-filled water.

As a result, he turned to an even tougher polymer material, Hitemp 150, which is designed to give good resistance to abrasion and to be especially suited for dirty applications.

Faced with highly abrasive conditions, the bushings lasted a year without a scratch, tells Pienaar.Pienaar also found Hitemp 150’s temperature characteristics useful.

With a temperature rating of 150ºC (300ºF), a short-term temperature limit of 170ºC (340ºF) and a melting point of 265ºC (509ºF), the material was also suitable for the harsh operating conditions that it would face, including having to run dry for limited periods. Pienaar notes that unattended pumps on golf courses can run dry for lengthy periods.

While this is not ideal for the pumps or the bushings, if the bushings are treated as sacrificial parts that protect the pump in a harsh environment, the Hitemp 150 polymer bushings do their job.

The bushings, which can withstand 1 minute of dry running, will eventually be affected by an environment in which water cooling does not occur. In extreme cases, the bushings melt on to the shaft, describes Pienaar.

This causes the motor to trip and the pump to cease to operate, he says, noting that this is preferable to damage that may be caused by a pump running dry for a lengthy period.Golf Turf Electronics has golf-course pump maintenance contracts in South Africa and Mauritius.

The company provides bowl bushings for the bottom of the pump shaft as well as intermediate support bushings. At the Sabi River Sun golf course, the company supplies bushings for two OEM canister pumps, each with a flow rate of 80m3/h.

Source: Vesconite Bearings