Table-Top Dosing Machine for Highly Viscous Materials

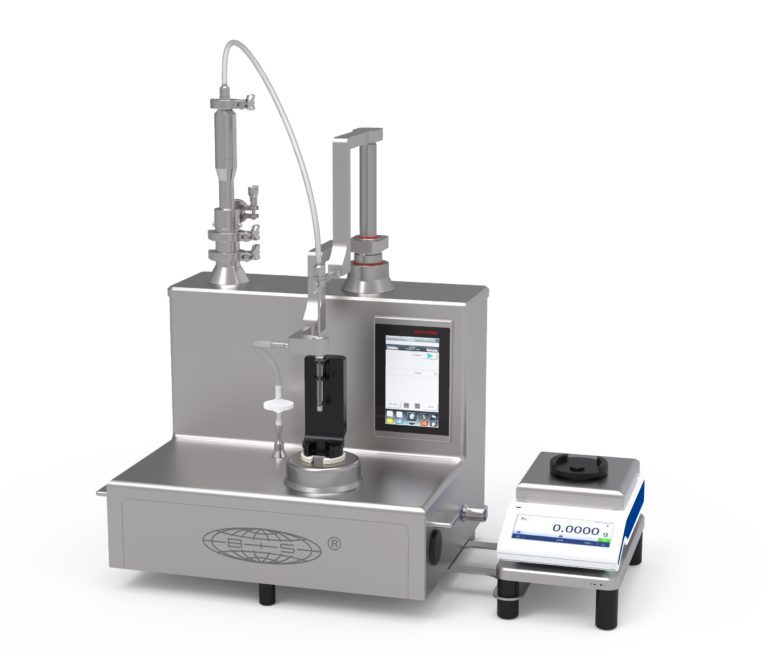

Bausch+Ströbel EDM 3721 dosing machine using the ViscoTec Hygienic Dispenser. (Image source: ViscoTec Pumpen- u. Dosiertechnik GmbH)

Bausch+Ströbel developed a new table-top solution for processing highly viscous products: The EDM 3721. The dosing machine is equipped with a ViscoTec dosing pump.

The EDM 3721 was specially developed for processing highly viscous, shear-sensitive and abrasive materials. The dosing of fluids and pastes can also be carried out under vacuum in syringes. Vacuum-assisted dosing leads, for example, allow a significantly lower amount of micro bubbles in the dosing material. The semi-automatic dosing machine is conveniently operated via a touch-screen panel. By means of scales, an in-process control of up to 100 % is possible, with automatic feedback adjustment of the dosage during production. Batch reports can be saved and printed using the printer supplied together with the machine equipment to provide a complete documentation of the dosing results.

ViscoTec Pharma Dispenser in Hygienic Design

The built-in dosing pump – a ViscoTec Pharma Dispenser in Hygienic Design (VPHD) – has been developed for use in a wide range of applications in the pharmaceutical and medical technology sectors. The dispenser has already proven itself in many applications worldwide. The dosing of low to high viscosity fluids and pastes is highly precise, gentle to the product and completely pulsation-free. Thanks to the built-in endless piston principle, the VPHD is also perfectly suited for shear-sensitive or abrasive materials. The structure of the fluids to be dosed is not affected. The built-in corrosion-resistant stainless-steel rotor moves eccentrically in a stator made of elastomer (FDA-compliant). The interaction of rotor and stator creates cavities. The size of the alternately opening cavities is completely constant during rotation – the conveyed product is not compressed. This geometry enables the desired, precise, gentle and pulsation-free product flow. In addition, programmable suck-back prevents dripping or stringing.

Quantities of 0.1 to 100 ml are dosed. In practice, the dosing accuracy usually exceeds the guaranteed value of +/- 1 %. The Pharma Dispenser can be completely disassembled and assembled without tools in just a few minutes. All components in contact with the product can be cleaned manually or in cleaning systems as well as in ultrasonic baths and sterilized in autoclaves.

The table-top machine from Bausch+Ströbel processes bottles, vials, disposable syringes and cartridges. The dosing machine is suitable for use in an isolator and therefore also for use in the flexible production system VarioSys from Bausch+Ströbel. The machine manufacturer is an expert in filling and packaging processes for the pharmaceutical industry. High quality pharmaceuticals are dosed worldwide on the filling and packaging lines.