Sulzer to Supply Pumps for Salt Caverns Storage Project in Canada

Sulzer received an order from Strathcona Storage Limited Partnership. The pumps Sulzer supplies are for the challenging application of injecting hydrocarbons at a very high pressure into salt caverns for storage. The pumps will be shipped in the first quarter of 2016.

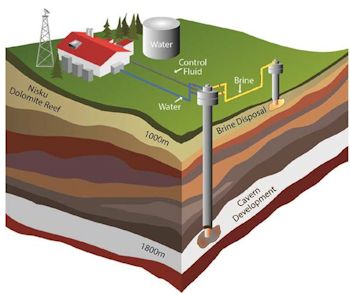

Illustration of the salt caverns storage project in Canada (Image: Sulzer)

Sulzer’s sales, tendering, and engineering teams from Canada, USA, and Brazil provided a solution that met the customer’s technical and commercial expectations. Besides the delivery, Sulzer will take care of training of the staff, repair, and other services as required for the complete life cycle of the pumps.

The CP Volute Style Pumps for the ethylene service will be designed, engineered, manufactured, and tested in Portland, USA. The GSG Diffuser Style Bare Shaft Pump will be designed, engineered, and manufactured in Jundiai, Brazil, and finally packaged and tested in Portland, USA.

Strathcona Storage Limited Partnership—a company formed in partnership between ATCO Energy Solutions Ltd. and Petrogas Energy Corp.—is developing four caverns with a total capacity to store 400 000 cubic meters of natural gas liquids. The first two caverns are targeted to go into operation in fall 2016, with the next pair ready in fall 2017. The project will help to move natural gas liquid (NGL) products to North American and international export markets.

Sulzer anticipates that this technology of storing propane, butane and ethylene will be used in the future by many other companies that are involved in temporary storage of light hydrocarbons in salt caverns. This technology of storage has a low impact on the environment.