Sulzer Supports TechnipFMC on Innovative CO2 Pumps for Subsea Oil and Gas Separation

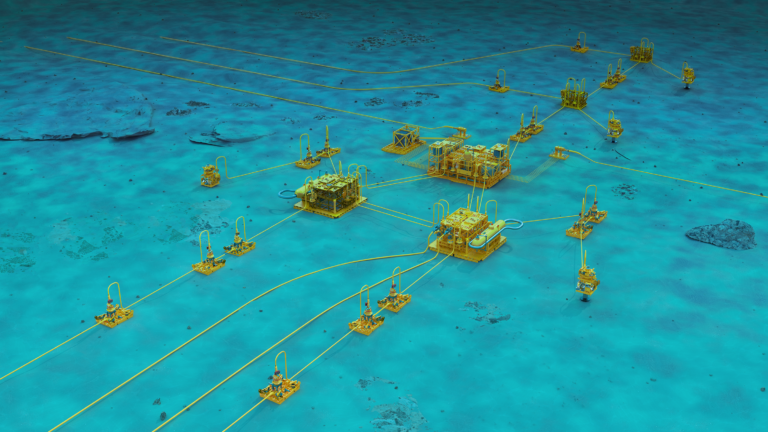

Sulzer has been selected by TechnipFMC to collaborate in developing new subsea CO2 pump solutions for new technologies (Image source: Sulzer Ltd.)

The process has the potential to provide significant gains in energy efficiency and productivity to Floating Production Storage and Offloading (FPSO) vessels while reducing costs and emissions.

Currently, the associated rich CO2 gas processed on FPSOs at topside needs to be treated and recompressed through large, energy-intensive compressors. While this allows the CO2 gas to be reinjected in the reservoir, it is highly energy intensive. The new pump technology will support and enable the gas stream, rich in CO2, to be separated and pumped immediately back into the reservoir at the seabed, 2000m below the water line, allowing FPSOs to improve their efficiency and reduce their carbon footprint, further enhancing production.

Sulzer Flow Equipment has been collaborating with TechnipFMC to develop and test supercritical CO2 pumps for Petrobras’ HISEP technology since 2017. Following the staged development and validation of a prototype, the pump expert is now supplying three customized 6 MW high-pressure centrifugal (HPcp) pumps for Petrobras’ planned HISEP pilot project in the Brazilian pre-salt oil region. The HISEP technology is supported by Petrobras and its partners in the Libra Consortium. Upon delivery, the pumps will be tested and validated to the highest standards in a purpose-built laboratory at the Federal University of Itajuba.

Head of the Flow Equipment Energy and Infrastructure Business Unit Jonathan Lloyd said: “We are excited to work with TechnipFMC and Petrobras to bring this remarkable new technology to life. By avoiding the need to process CO2 on the FPSO, this collaboration allows significant energy efficiency and topside space advantages. The project underscores Sulzer’s long-term heritage and commitment to innovation, cementing it as a leader in new pump technology, as well as its value in close partnerships to drive cleaner, more efficient and profitable growth.”

Luana Duffe, Executive Vice President, New Energy, at TechnipFMC said: “With the HISEP project, we will again demonstrate how our leadership in subsea processing, technology innovation, and integrated solutions can deliver real and sustainable benefits to our partners. Sulzer is an expert in market-leading pump solutions for the industry’s most demanding processes and is a go-to partner for the Mero 3 HISEP project. This project has truly been a shared journey of innovation for all of us.”

Petrobras’ HISEP project will be deployed at the Mero 3 development in the Brazilian pre-salt oil region, where fields typically contain a 50/50 mix of oil and CO2-rich gas. Mero 3 is being developed by the Libra Consortium, operated by Petrobras (38.6%), along with partners Shell Brasil (19.3%), TotalEnergies (19.3%), CNPC (9.65%), CNOOC (9.65%) and Pré-Sal Petróleo SA (PPSA) (3.5%), representing the government in the non-contracted area.

Source: Sulzer Ltd.