Smart Miniature Pump

An innovative micro-pump makes it possible for tiny quantities of liquid – such as medicines – to be dosed accurately and flexibly.

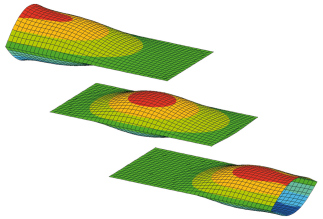

The novel micro-pump works in a similar way to the human esophagus: The liquid is ingested from the left (above), propelled forward by contractions of the pump (center) and released on the right (below) (Photo: Fraunhofer-Gesellschaft, Germany).

Active composites and an electronic control mechanism ensure that the low-maintenance pump works accurately – both forwards and backwards.

Medicines sometimes have to be administered in extremely small quantities. Just a few tenths of a milliliter may be sufficient to give the patient the ideal treatment. Micro-pumps greatly facilitate the dosage of minute quantities. Pumps like these have been built and constantly optimized for over 25 years. They find application in numerous areas – from medical engineering to microproduction technology – wherever tiny volumes have to be variably dosed with extreme accuracy.

However, these micro-pump systems are usually not as flexible as desired: They often work in only one direction, bubbles in the liquid impair their operation, they do not tolerate bothersome particles, they have a fixed pump output and they contain expendable parts such as valves or cogwheels. Together with partners from research institutes and industry, researchers at the Fraunhofer Institute for Mechanics of Materials IWM in Freiburg have developed an innovative pump system that solves all these problems: a controllable peristaltic micro-pump. “The peristaltic pump is a highly complex system,” explains IWM project manager Dr. Bärbel Thielicke. “It contracts in waves in a similar way to the human esophagus, and thus propels the liquid along – it changes shape of its own accord. To achieve this, we had to use a whole range of different materials and special material composites.” The researchers use lead-zirconate-titanate (PZT) films that are joined in a suitable way with bending elements made of carbon-fiber-reinforced plastic and a flexible tube. “PZT materials change their shape as soon as you apply an electric field to them. This makes it possible to control the pump system electronically,” says Thielicke. Special adhesives additionally hold the various components of the pump system together. Thanks to the special control electronics, tiny quantities can be pumped accurately through the system.

The peristaltic pump system has already passed its first functional tests. Now the researchers are working to adapt the peristaltic micro-pump to the various different applications. “We work with special simulation models to do this,” says Thielicke. “We calculate in advance how the structure of the pump needs to be modified in order to administer other dosages or other liquids. This helps us save time and money during the development phase.”