Sensor Protects Against Total Failure

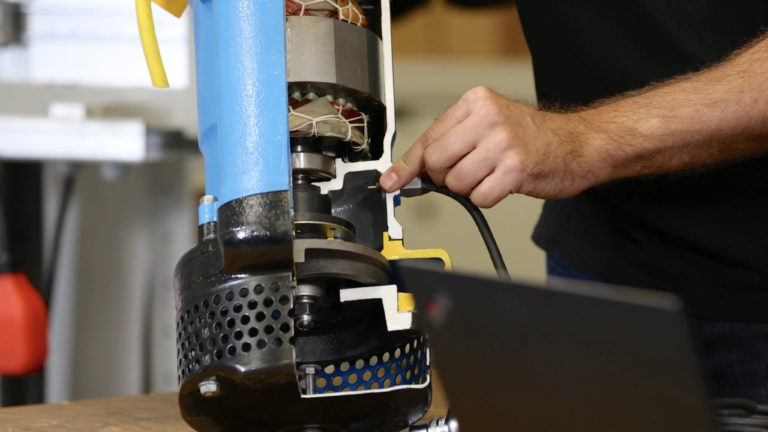

Recommended retrofit: The cutaway model shows the position of Tsurumi's leakage sensor, which is basically an oil screw with an extended function (Image source: Tsurumi (Europe) GmbH)

The manufacturer had to use a trick for this, because such a retrofit is not technically provided for: the pumps are designed so robustly that they run safely and reliably in normal operation. However, it can never be ruled out that the abrasive force of the water flow will overcome all the built-in barriers.

Critical points for probably all manufacturers are the cable entry and the mechanical seal at the bottom of the housing. Tsurumi's protective measures at these points: Each electrical conductor is encapsulated in synthetic resin to exclude creeping moisture. And the double internal seal of the oil chamber is made of silicon carbide, almost as hard as diamond. Clever: the manufacturer has integrated the sensor into the screw of the oil drain. Installation is literally done in no time: old screw out, new in.

To detect water ingress into the housing via the oil chamber, the sensor measures the electrical conductivity of the lubricating oil. Pure oil conducts almost no current. So if the electrical resistance is consistently low, water must have entered. Then the pump should be switched off immediately to prevent lubrication damage or water being drawn into the engine compartment. Also, the risk of electric hazard to the user should never be underestimated. Replacing the seal solves the problem and makes the pump ready again. Thanks to Tsurumi's modular design, the work can be done by the user himself.

The sensor cable goes to the control cabinet, where Tsurumi's "smart" Connect Box may also be installed. This switches the pump off and informs the user, for example, via a message on the mobile phone network. At the same time, other operating parameters can be called up and monitored. Alternatively, a relay is sufficient to turn off the pump when the sensor activates. The retrofit part is called TSS-TEG and should help significantly to save the pump and the dewatering project from a major failure.

Source: Tsurumi (Europe) GmbH