Rurpumpen: Impeller Lift Procedure

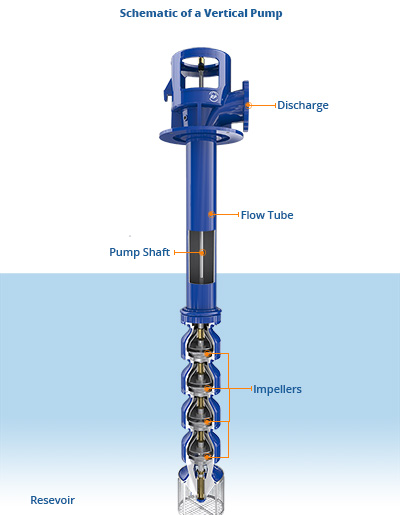

All vertical pumps need the adjustment of impeller clearances before any attempt is made to start the pump. Only at the precise clearance, specified by the pump manufacturer, the pump efficiency will be at its maximum.(Image source: Ruhrpumpen)

Due to their design, during assembly, the impellers “rest” on the casing or bowl. The impeller vanes must always be parallel to the surface of the bowl leaving a gap, which is known as the clearance. To operate efficiently, the impeller vanes need to comply with the clearance they were designed for.

If the clearance is too large, it may cause recirculation from the high pressure portion of the pump to the lower pressure portion. This can lead to a great loss in efficiency and the accelerated erosion of the bowl. Contrarily, if the clearance is too tight, the hydraulic friction will also decrease efficiency. In addition, there may be scrapping of the impeller with the bowl, causing permanent damage to both parts and shortening the service life of the pump.

Since the vertical pump assembly (impellers and bowls) is normally immersed and inaccessible, this adjustment is done at the top of the pump. The impellers are allowed to rest on the bowl by loosening the pump shaft from the motor shaft. This is the “zero” clearance position. The shaft is then lifted upwards, with the use of certain tools, until the clearance is well adjusted.

Source: Ruhrpumpen GmbH