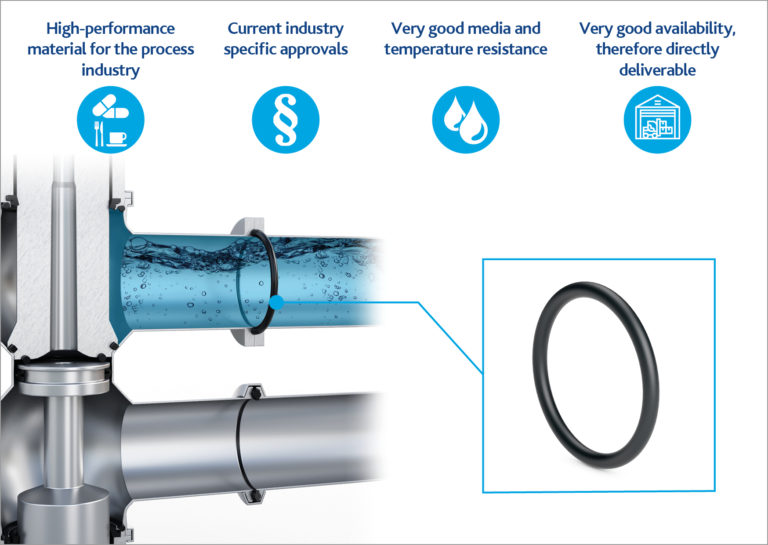

Peroxidic-Crosslinked Fluoroelastomer from Freudenberg Meets the Latest Regulatory Requirements of the Process Industry

(Image source: Freudenberg Sealing Technologies GmbH &Co. KG)

The immediately available high-performance material is very resistant to media and temperature, ultrapure and thus one of the company's product highlights at the Interphex trade fair from April 25-27 in New York and at the FoodPro trade fair from July 23-26 in Melbourne. Fluororubber has become an integral material for the process industry. It is suitable for applications under high temperatures and with aggressive media. These properties are critically important for the food and beverage as well as in the pharmaceutical industries. Those beneficial properties lead to high demand for the material and this in turn to long delivery times. The material from Freudenberg Sealing Technologies meets high purity standards and is strongly resistant to media and temperature. In addition, it scores with its good availability.

Meeting long-term regulatory requirements

Thanks to the dedicated work of the material developers, the elastomer also meets all current regulatory requirements of the process industry in the long term. These include, on the one hand, certifications and approvals that ensure that materials that come into contact with food do not transfer harmful substances to the food [EU (Reg.) 1935/2004, FDA § 177.2600 and BfR XXI]. "This uncompromisingly complies with the latest regulations," explains Dr. Martin Scherer, material developer at Freudenberg Sealing Technologies. "This is important because there are constant updates on the cleanliness of food contact materials, especially in Europe." Furthermore, the USP Chapter 87 (in vitro) confirmation required for use in medical and pharmaceutical applications is available, which proves that the material has no toxic effects on cell cultures. The strict hygienic requirements of the food and pharmaceutical industries for the elastomer are met with the certification according to 3-A Sanitary Standards. In addition, the material does not contain any ingredients of animal origin. The USP Class VI (Chapter 88) approval, which is important for use in medical applications, is currently still in progress. The peroxidic-crosslinked material offers very good resistance to aggressive process media and is toxicologically completely harmless based on the release tests carried out. These outstanding properties compared to commercially available materials and the very wide range of applications at temperatures from -25 °C to +200 °C make it the ideal material for product-contacting applications in the food, beverage, and pharmaceutical industries.

High-performance material for demanding tasks

The new FKM is well suited for applications where seals made of other elastomers, such as EPDM or HNBR, are too weak. For example, in processes in the beverage industry involving pure citrus juices, dairy products or aromatic oils, such as orange or hop oil. In addition, a benchmark study conducted by Freudenberg Sealing Technologies proves the material's high resistance to aggressive cleaning media. In long-term tests with comparable FKM materials in concentrated CIP media, the new FKM was able to convince with its very good chemical resistance. Currently, O-rings and diaphragms for pumps are already being manufactured from this high-performance material; the development and production of customer-specific sealing solutions is planned. The fluoroplastics and rubbers used by Freudenberg Sealing Technologies belong to the group of polymeric per- and polyfluoroalkyl substances. These large, long-chain molecules are classified as safe for humans and nature by expert bodies such as the OECD. When used and disposed of properly, there is no risk to human health and the environment. The material experts at Freudenberg Sealing Technologies follow the legal regulations very closely. All of the company's fluoropolymer suppliers must confirm that they comply with the thresholds for already restricted PFAS chemicals and Freudenberg verifies this information with their own analyses in the laboratory. Together with relevant industry bodies, the company is currently examining the draft of the EU-PFAS restriction published in mid-February. The deadlines for public statements and consultation of the bodies on the new EU legislation run until the beginning of 2024. The restriction is to enter into force in 2025 with a transitional period of 1.5 years; to what extent is still largely unclear.

Source: Freudenberg FST GmbH