Overcoming Chemical Dosing Challenges in Wastewater Treatment

Adeel Hassan (Image source: Watson-Marlow Fluid Technology Solutions)

If the effluent water is going to be discharged back into the environment, it must be treated to comply with regulatory requirements and prevent damage to ecosystems and human health. Alternatively, many industrial companies want to reuse their wastewater to minimize their environmental impact, reduce costs and overcome water shortages. For this purpose, the wastewater must be treated so that it is suitable for its new purpose, such as industrial cooling water.

Wastewater treatment providers are facing the challenge of effectively handling a variety of treatment chemicals, as well as external factors such as increasing demand and the drive for sustainability. Here Adeel Hassan, product manager at Watson-Marlow Fluid Technology Solutions, shares his insight into how wastewater treatment providers can overcome different process challenges by upgrading their pumping technology.

Disinfection and neutralization

Chemical disinfection involves the use of oxidizing chemicals, such as sodium hypochlorite. However, oxidizingchemicals off-gas, causing gas to be present in the fluid. This gas can block a diaphragm pump by preventing correct operation of the ball valves. Wastewater treatment providers can overcome this by selecting peristaltic pumps, which push any gas present in the fluid through the pump without causing any maintenance issues.

Sustainability is driving the use of higher concentration chemicals to minimize transport costs and emissions, as well as reduce the size of dosing systems. However, high concentration chemicals, such as sulfuric acid used in neutralization, can be hazardous if not contained after a pump failure. Therefore, it is important that plant managers select a pump that is compatible with high concentration chemicals and prevents chemical exposure to the operator.

High concentration chemicals require a very accurate and repeatable pump to maintain process capability. Peristaltic pumps with low pulsation and no ball valves result in parts per million (ppm) concentrations with very low standard deviations, minimizing chemical usage and maximizing process quality.

Coagulants and flocculants

Regulations around preventing eutrophication are driving the removal of phosphates from wastewater. Ferric chloride, commonly used in this process, reacts aggressively with metal pumps. By selecting a pump with a plastic case, wastewater treatment providers can ensure their equipment is compatible with ferric chloride systems.

Furthermore, in diaphragm pumps, ferric chloride can pose a threat of solid content becoming stuck under the ball valves that are keeping the pump open. If both valves become stuck, then the pump can start to siphon, and the fluid will travel in the opposite direction as it can flow out of the pump. This creates inaccuracy as the fluid is leaking out. By selecting a peristaltic pump that does not require any valves, these challenges can be avoided completely.

Polymers are commonly used for dewatering of sludge and solids removal from water. Solids removal helps to clean the water for reuse, while dewatering sludge minimizes bulk, which can reduce costs associated with storage and disposal by up to 75 per cent. Efficient polymer activation is essential in increasing the efficacy of the polymer and minimizing usage. The creation and integrity of polymer chains requires a constant stream of polymer into the dissolution stage, which can be achieved by using a low pulsation pump.

If condensation gets into the source tank, then polymers can agglomerate together and block the valves of some pumps, such as diaphragm pumps. This plugs the discharge of the pump and can cause it to breakdown. This can be avoided completely with peristaltic pumps, which require no valves to operate.

Urbanization

As well as the variety of different chemicals in wastewater treatment providing dosing challenges, the wastewater industry must contend with external factors. Urbanization means more people are living closer together in towns and cities, increasing the amount of municipal wastewater in one area. The resultant wastewater means bigger wastewater treatment works with larger processing systems are needed.

Therefore, wastewater treatment providers require more powerful pumps with high flow rates and low pulsation to increase efficiency and meet demand. While diaphragm pumps meet the capacity requirements, they can only offer low pulsation when operated at low flow rates. Instead, plant managers should opt for a peristaltic pump that offers low pulsation even at high flow rates.

Rising to the challenge

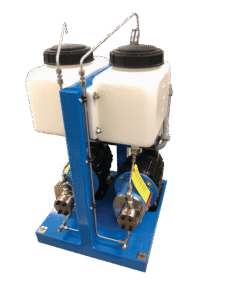

After calls from plant managers for more powerful and adaptable pumping equipment that enables accurate, flexible and high capacity dosing, the Qdos H-FLO was designed. The pump is capable of flow rates up to 600 liters per hour and can handle pressures up to 7 bar via a range of interchangeable pump heads. The different pumpheads enable the pump to be used in a wide range of wastewater applications and allow plant managers to respond quickly as treatment processing requirements change.

The Qdos H-FLO has a pressure sensor that detects leaks and blockages. The pump stops before the system becomes damaged and alerts the operator with diagnostic feedback. In addition, all of the chemicals are safely contained within the pumphead, preventing operator exposure. If there is a problem, the pumphead can just be changed.

The twin-tube technology provides extremely low pulsation, with an offset rotor design protecting pipework integrity and providing consistent chemical supply compared with diaphragm pumps delivering similar flow rates. Unlike diaphragm pumps, the Qdos H-FLO has no valves, eliminating the issue of valves becoming stuck or blocked. In addition, the pump has a high accuracy of ±1%, which prevents chemical waste and saves costs.

Wastewater treatment providers face a variety of operating challenges, including handling a wide range of chemicals, meeting high demand, and becoming more sustainable. However, with the correct pumping technology, wastewater plant managers can ensure their operations run efficiently, accurately and safely.

By: Adeel Hassan, product manager at WMFTS