Optimized Pump Head for LEWA Ecoflow Pumps Doubles Volumetric Efficiency

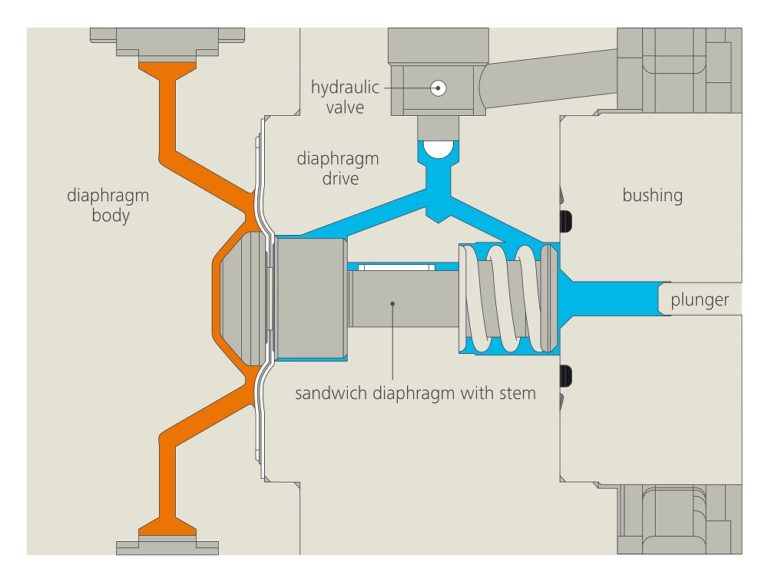

The geometric optimization of the M900 reduced the clearance volume in the pump head by about 51 percent on the fluid side and by about 22 percent on the hydraulic side. This equals a total clearance volume savings of 37 percent. The clearance volume at the rear dead center of the plunger is shown in orange (fluid) and blue (hydraulic) in the figure. (Image source: LEWA GmbH)

The LEWA M900 is a pump head with a hydraulically actuated diaphragm made of pure PTFE and a diaphragm holder made of stainless steel. It is designed for universal use and is used on all LEWA Ecoflow pumps as well as on LEWA process pumps for medium flow rates. The pump head has a whole range of advantages. It is not only hermetically tight so that leakages of pumped fluid or hydraulic oil are impossible, but is also characterized by high metering accuracy, optimum suction capacity due to the diaphragm spring, and a very long diaphragm service life.

Low volumetric efficiency at pressures > 150 bar

The previous M900 diaphragm pump head for plunger sizes of 5-12 mm had a comparatively low volumetric efficiency on the LDB and LDC drive units with the smallest LEWA sandwich diaphragm at high discharge pressures with plunger diameters of 5 and 6 mm. "The reason for this is the clearance volume in the pump head," said Moritz Mildner, RD Engineer at LEWA. "'Clearance volume' is the volume that is compressed with each pump stroke during pump operation. It includes the hydraulic and fluid work spaces." The assumption that fluids are incompressible only applies to low pressures. In this case, it must be taken into account that although the reduction in volume for water and hydraulic oil is only about one percent at 100 bar, it increases to about 10 times this amount at 400 bar due to the pressure dependence of the compressibilities. "As the pressure builds up in the pump, the fluids are compressed until the discharge pressure is reached," Mildner explained. "The result is a reduction in displaced volume equal to the volume reduction that occurs when the fluids are compressed." The ratio of displaced volume to the ideal, theoretical displacement volume is referred to as the volumetric efficiency. If the volumetric efficiency of a pump decreases, its energy efficiency and cost-effectiveness also decrease.

For this reason, LEWA limited the use of the previous M900 pump heads to 100 or 150 bar. Instead, M200 pump heads with metal diaphragms were used for applications with low flow rate (< 1 l/h) and a discharge pressure between 150 and 400 bar. "However, those models do not have some key advantages of the M900, such as lower minimum suction flange pressure or more robust hydraulics due to the diaphragm spring," Mildner explained.

Adapted pump head with significantly reduced clearance volume

To be able to use the advantages of the M900 technology in higher pressure ranges as well, LEWA decided to redesign the pump head for such applications. Since the design of the previous pump head was based on the 12 mm plunger and, compared to the two small plungers (diameter 5 and 6 mm), took into account 4 times and 4.8 times the stroke volume, respectively, as well as correspondingly greater flow velocities of the conveying and hydraulic fluid within the components, extensive adjustments had to be made. "By designing a diaphragm body and diaphragm drive specifically optimized for the small plunger sizes, we were able to reduce the flow paths in the hydraulics, the installation space of the diaphragm spring, the diaphragm calotte, and the fluid bores on the pressure and suction sides," Mildner said. The geometric optimization reduced the clearance volume in the pump head by about 51 percent on the fluid side and by about 22 percent on the hydraulic side. This equals a total clearance volume savings of 37 percent.

Within the scope of the revision, the calotte posed by far the greatest challenge. For its optimization, the actual diaphragm movement was first studied using laser measurement technology. For this purpose, LEWA produced a special pump head that allows a view of the normally invisible diaphragm in its installed state. "The position of the diaphragm and the diaphragm holder in the front end position were relevant for the depth of the calotte," explained Mildner. "That is why the diaphragm contour was scanned with the help of two lasers." One laser was used to determine the current height of the movable measuring device and the second for the deflection of the sandwich diaphragm. In this way, the center plane was completely measured for plunger sizes 5 mm and 6 mm, and different stroke frequencies. Based on the envelopes generated from the point clouds, it was possible to geometrically adjust the fluid working space in the diaphragm body to the actual diaphragm motion.

Significant increase in volumetric efficiency

Next, the research and development team conducted a series of tests to validate the new pump head. The essential functions of the hydraulics – gas discharge, sniffing function and pressure limitation – were checked and the volumetric efficiency was determined via the characteristic diagram of the diaphragm pump head. At the maximum pressure of 400 bar, process water was used to achieve a volumetric efficiency of 40.2 percent for the 5-mm-diameter plunger and 56.3 percent for the 6-mm-diameter plunger. These values were 19.9 and 39.0 percent respectively for the previous diaphragm pump head. The new M900 is thus ideally suited for use with the Ecoflow pumps LDB and LDC at low flow rates and up to 400 bar discharge pressure.

Source: LEWA GmbH