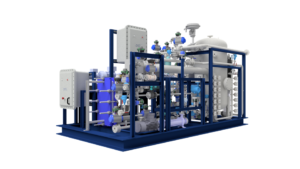

New Lower-Flow Twin Screw Pumps Improve Accuracy and Process Economy

Improve accuracy and process economy with new lower-flow Twin Screw Pumps. (Image source: Alfa Laval Corporate AB)

Need to go low flow? Go with the Alfa Laval Twin Screw Pump

Designed for process flexibility, the Alfa Laval Twin Screw Pump is built on a robust, reliable platform that meets stringent hygienic standards. It is capable of handling both product transfer and Cleaning-in-Place (CIP). Its low pulsation characteristics and excellent solids handling capability reduce the risk of product damage, thereby improving product quality. Maintenance is simplified and process uptime increased.

More economical operation

Less is more. By increasing the performance envelope of the pump, you reap the benefits of lower flow rates yet get better accuracy, higher volumetric efficiency and more economical operation.

Greater process flexibility and cost savings

Like all Alfa Laval Twin Screw Pumps, these small, but mighty new models excel at multi-duty applications, handling both product transfer and cleaning duties. This eliminates the need for a separate Cleaning-in-Place pump and bypass piping. Cost savings add up thanks to a truly front-loading cartridge seal that simplifies maintenance and extends process uptime.

Higher product quality with virtually pulse-free operation

The new compact, lower-flow Twin Screw Pumps are the right choices for low-shear transfer of sensitive, abrasive and high and low viscosity fluids with high large solids content. Low pulsation characteristics greatly reduce the risk of product damage, thereby improving product quality.

Pump Portfolio Manager at Alfa Laval, John Walker explains: "Optimized for lower-flow product transfer, the three new Twin Screw Pump models extend the current pump range to deliver higher accuracy and process economy. This boosts both product quality and yield."

Source: ALFA LAVAL Corporate AB