Modular Microliter Pump for Small Flow Rates (5μl – 3ml/min.)

DNE microtechnology and 2E mechatronic have developed a new pump system for conveying a wide variety of fluids. It combines all the benefits of different pumps, like for example diaphragm, piston injection and peristaltic pumps. The aim was to develop a reliable pump with an exchangeable fluidic part which, due to its modular construction, is capable of conveying a variety of fluids parallel.

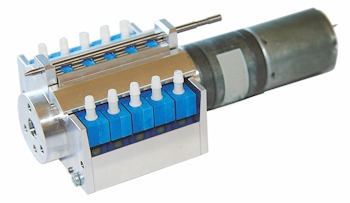

Modular Microliter Pump (Image: 2E mechatronic GmbH & Co.KG)

Basic model with two to five flow channel

The basic pump has a maximum of five independent flow channels. This guarantees that in each channel a defined volume can be conveyed independently of pressure fluctuations in neighbouring channels.

Extendable to a maximum of 10 channels

The modular construction makes it possible to increase the number of channels to a maximum of 10. Tubes with different internal diameters are available which can be flexibly inserted into each channel.

Wide flow volume range

The flow rate of the pump can be varied due to its modular construction. This can be achieved, for example, by varying the gears in the motor or by using tubes with different internal diameters.

Flow volumes can thus range from a few microlitres to several millilitres per minute.

Disposable fluidic part

The inexpensive fluidic part of the pump which comes into contact with the conveyed material can be exchanged by means of a simple coupling action. The drive unit comprising a drive motor, gear box, housing and actuator can thus be utilized several times. This contributes to a reduction in operating costs and protection of the environment.

Application

The pump was developed for use in laboratories or for analytic purposes. Cross-contamination can be avoided by regularly exchanging the fluidic part. Thanks to its multiple possibilities the pump can, however, be used also in other areas.

Prototypes are already in their test phase and further developments are underway with the aim of also using the system for a single-channel pump.

Source: 2E mechatronic GmbH & Co. KG