Lowara Submersible Pumps Aid Geothermal System

UPC is a multinational provider of TV, Internet and telephone services and has one of their main call-centres based in Leeuwarden, Netherlands. With over 1,500 employees and hundreds of computer screens giving off heat, the task of cooling the premises is far bigger than heating it.

Xylem Water Solutions

Xylem Water Solutions were contacted by industrial designers Remon Aardwarmte and given the task of providing a solution to help regulate the temperature throughout the entire building.

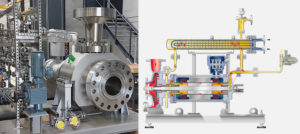

After careful consideration, Xylem recommend the use of Lowara aquifer thermal energy storage (ATES) submersible pumps thanks to its reliability and geothermal capabilites.

“In an installation as complex as this one, every piece of equipment matters”, said Mr Alex Vaatstra, Product Manager of Remon Aardwarmte.

“But submersible pumps play a role that is really crucial. In the case of a malfunction, we cannot simply carry out repair works on the pumps as they will be located approximately 70 meters underground, in a closed, almost inaccessible area. That’s why the equipment needs to be extremely reliable, with a long service life, capacity of 5 to 35 m3/u for many years in properly salted atmosphere as well as geothermal capabilities. That was the reason why we opted for two pre-set, ATES-system-compatible Lowara submersible pumps.”

How geothermal works

Geothermal heating/cooling systems operate via a sub-surface conductive heat transfer, using the naturally renewable temperature of the earth’s crust as a heat source in the winter and as a heat sink the in the summer.

In cooling mode operation, the hot refrigerant liquid is sent far below the earth’s surface, which absorbs and takes heat away. The cooled refrigerant liquid is then circulated through the air handler where it absorbs and removes unwanted heat from the interior air. This process is constantly repeated thus removing your heat for free.

In heating mode operation, naturally occuring heat from deep within the earth travels to, and is absorbed by, a much colder refrigerant liquid that is circulated within copper tubing inside a deep well/borehole. This naturally occuring heat is then transported to by the refrigerant fluid and is compressed, thereby raising it’s pressure and temperature. The hot refrigerant is then circualted through finned tubing within an air handler, where the cold return interior air absorbs the heat. The heated air is supplied via a fan to the interior air space. With the heat now removed from the refrigerant liquid, it becomes very cold and is re-circulated into the ground to absorb more naturally occuring and renewable heat, thus supplying your heat for free.

Energy efficient utility building

“Only Lowara submersible pumps have leakage-guaranteed check valves, meaning that, at standstill, the pressure in the system remains identical” says Alex Vaatstra. “This is a perfect example of an energy efficient utility building as the efficiency of the submersible pumps is extremely high, up to approximately eight per cent. The engine especially developed for the ATES-system in AISI 316 grants a great adjustment range of 18-60 Hz and allows for an ideal heat transmission. Even after this configuration, the efficiency remains high.

“Also, with such a low rotation speed, the pump still transmits pressure and maintains an efficiency of approximately eighty per cent, which make the Lowara ATES submersible pumps so vital to the operation of the heating and cooling system.”

No more filter blockages

“One of the main reasons for choosing Lowara pumps is their durability”

“They can function smoothly for between 15 – 30 years which is exactly what you want from a piece of equipment that works 70 meters underground”, says Mr Vaatstra.

“In addition, Lowara submersible pumps offers for water tight retaining valves. “If the spring is not in use, the pressure in the system has to remain constant. If it decreases, dissolved gasses develop in water and, for example, methane and oxygen can be freed. The free oxygen can react with the iron in water, creating ferrous oxide that can flocculate and, if flocculation happens in the spring system, the infiltration filter is clogged and the system doesn’t work anymore. As a consequence, substantial, time-consuming, long and expensive procedures are needed, sometimes even chemical washing.”

Continuing performance

After the building was inaugurated, the area was hit by a very cold winter, with temperatures reaching -20°C. “That was such a stroke of luck for us”, added Mr Van Vaatstra, “because we had been able to store extra cold for our first summer.

“A regeneration system was studied to neutralise possible energy imbalances. In the nearby Harlingertrekweg building, the available 4°C cold water is used to cool the “hot” water even further and then stored in the “cold well” for the following summer. In this way it is possible to produce more cold than what the building needs.

“For the pumping of the canal water from the Harlingertrekvaart, an energy efficient Lowara SHE-pump was chosen”

Thanks to an innovative system, this centrifugal pump is now a self-priming pump, a feature that makes it even more energy efficient.

“It is quite clear that the system works properly with high outdoor temperatures too. After two season changes, the wells have “reached” the right temperature and they indicate that the geothermal energy for heat and cold supply has stayed balanced.

“The Geothermal system has had a huge impact on the energy efficiency of the entire premises, so much so that this building was the first to be awarded a BREEAM NL Excellent certification.”

Source: Xylem Inc.