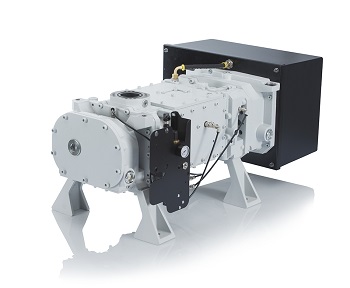

Leybold Complements Vacuum Screw Pump Series Dryvac with Further Variants

The latest addition to the industrial dry pump portfolio is the Dryvac DV 200 and DV 300. These pump sizes complement the already existing product range of Dryvac 450, 650 and 1200 and offer the same user benefits for applications requiring smaller sizes.This series of dry compressing screw-type vacuum pumps is engineered for the new era of smart manufacturing.

Leybold-Dryvac 200 and 300 (Image: Leybold GmbH)

Packed with intelligent features and functions, all Dryvac models offer benchmark energy efficiency, durability and future ready network-integration.

Benchmark energy consumption

Exceptional low constant power consumption delivers world-class energy efficiency. Due to an optimized screw rotor design, the DV200/300 minimizes the power consumption, saving costs and reducing your carbon footprint. Dryvac pumps are more cost-efficient and greener than similar models.

Durability

Just as the already known DRYVAC pumps, the Dryvac DV 200 & DV 300 are designed for harshest industrial conditions and offer a long life span, despite demanding parameters such as vapors, dust and particles. Dryvac pumps also feature minimal maintenance and easy cleaning of water cooling channels. The DV200/300 is equipped with an automatic shaft seal purge control for optimal protection of shaft seals and bearings.

Future ready-connectivity & networking

Fieldbus and PLC compatibility allow for connectivity to other devices in a network for real-time communications and control. Direct control is also possible via a computer or handheld device. Support for various fieldbus protocols ensures maximal flexibility. Plug connections for I/O and RS485 interface are available on each DV200/300. Protocol support for Ethernet/IP, ProfiNet, Profibus and EtherCAT is easy by optional cards. Dryvacs speak proverbial every language.

Characteristics

- Hermetically sealed screw vacuum pump

- Simple mechanical and electrical integration due to intelligent on board frequency converter

- Plug connections for I/O and RS485 interface outside of the pump

- Integrated protection functions of temperature, exhaust pressure and power consumption monitoring

- Small footprint due to compact design

- Low energy consumption achieved through optimized rotor geometry and innovative motor design with efficiency class IE3

- Tolerant to dust ingress

- Excellent water vapor performance

- High pumping speed also at high intake pressures

- IP54 protection level

- Made of super durable GGG40.

Source: Leybold GmbH