Lewa Diaphragm Metering Pump for Plant Engineering

When discharging or metering fluids, industrial system operators must often observe rigid safety and environment aspects and also meet the requirements of individual processes.

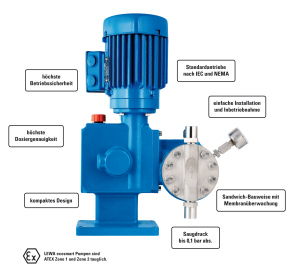

Lewa ecosmart (Photo: Lewa)

Now Lewa’s engineers have used their long-term experience to develop a diaphragm metering pump for intermediate requirements and small investment budgets. The new LEWA ecosmart series offers the best price-performance ratio in this class (80 bar, 120°C, 300 l/h) and meters, thanks to the proven variable eccentric drive, reliably, reproducibly and precisely. Different stroke frequencies of the drives allow adaptation to diverse fluids and process requirements. The hermetically tight diaphragm pump also convinces with its dimensions: No other metering pump in this performance range is more compact.

Typical fields of application include:

- Water treatment in power plants

- Metering of additives in industrial water processing

- pH adjustment

- Dosing of solvents in the chemical industry

- Feeding of corrosion inhibitors

- Dosing of colorants and flavors in the food industry

- Additive metering in the plastics industry

- Injection of chemicals in the oil & gas industry

The design is based on the manufacturer’s well-known and solid technology – using for example the PTFE sandwich diaphragm with diaphragm monitoring, the patented diaphragm protection system (DPS) and optimized check valves. Lewa ecosmart also has no problems complying with the rigid safety standards of API 675 (American Petroleum Institute).

The sandwich diaphragm design with diaphragm monitoring ensures high availability. This technology reliably reports any damaged diaphragm. Yet the pump remains leakage-tight, and operations can continue for a certain time. An individually adjustable pressure relief valve prevents potential overload situations of the pump.

The low investment and operating costs are as convincing as the simple operations and the robust longevity of the pumps. Four sizes cover flow rates up to 300 l/h. The drive system uses three-phase and AC motors according to IEC and NEMA; frequency control for speed adjustment is also possible. Individual configurations are optionally possible, such as offshore paint, material test certificates or testing according to API.

Source: LEWA GmbH