Flexible Energy Savings with Frequency Inverters by Bitzer

Bitzer will be presenting the Varipack product series. All Bitzer reciprocating compressors can be operated with this new generation of intelligent frequency inverters. They feature impressive user-friendliness, reliability and high capacity.

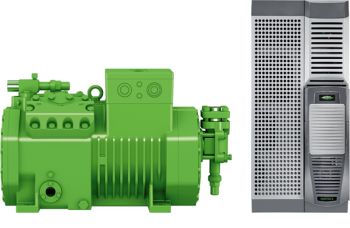

The new Varipack product series is designed for safe and easy capacity control and was specially adapted to suit refrigeration and operation of Bitzer refrigeration compressors (Image: Bitzer)

The new Varipack product series is designed for safe and easy capacity control and was specially adapted to suit refrigeration and operation of BITZER refrigeration compressors. After intuitive commissioning, the frequency inverters take over the control functions of the refrigeration system. Optimised adjustment to suit the system’s current cooling demand reduces energy consumption as well as running costs. With its modular design, the Varipack series achieves a high degree of flexibility and opens up a wide spectrum of variants for a large application range in supermarkets, hotels, restaurants as well as food production and processing centres. The series is suitable for refrigeration systems, air conditioning systems and heat pumps and can be integrated both in single compressors and in compound systems.

Varipack frequency inverters can be operated in two modes: the compressor capacity control either depends on an external set point signal or on the evaporation pressure with an optionally available add-on module for pressure control. In addition to direct control of the evaporation pressure, the condenser fan can also be regulated via a 0–10 V output signal and a second compressor can also be switched on. The frequency inverters can either be integrated completely in a switchboard or mounted via push-through installation as desired. With the second option, smaller switchboards offer sufficient space, because the cooling body protrudes out and therefore a majority of the generated heat is discharged directly outside.

Easy operation and high efficiency

An application-specific selection of frequency inverters is possible with Bitzer Software, and the BEST (BitzerElectronics Service Tool) software can be used for easy operation and monitoring. Stored databases allow for complete configuration of each compressor simply by selecting the compressor model. The new products are safe and reliable thanks to optimal harmonisation with Bitzer refrigeration compressors – choosing from preconfigured datasets prevents incorrect configuration. A high starting current reserve and special start-up behaviour also ensure safe compressor start-up. Thanks to their intelligent operation, the Varipack frequency inverters ensure that when working in field-weakening mode, the maximum frequency is automatically limited depending on the load. At market launch, the databases already contain data for more than 35 refrigerants. The frequency inverters demonstrate impressive efficiency in operation.

Thanks to the flexibility of the Varipack series in connection with configuration using Bitzer Software, users can select the optimal combination of compressor, motor and frequency inverter for every application. Communication for configuration, monitoring and reading out error messages takes place via the BEST software, the control unit or the integrated Web server. Bitzer has focused on user-friendly, intuitive operation in every case.

Source: BITZER Kühlmaschinenbau GmbH