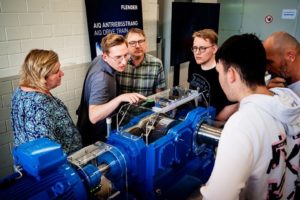

Flender Presents A New Double-Cardanic Coupling Variant

The N-Eupex DK adds a double-cardanic variant to the already existing short and long construction types. (Image source: Flender GmbH)

The introduction of the second elastomer joint increases the damping properties of the coupling and results in a lower torsional stiffness. This reduces vibrations, and the adjacent machine components are less stressed. In addition, the possible radial offset is increased more than fourfold. The restoring forces are thus reduced by more than half depending on size, offset and installation dimension. The encapsulation of the elastomers ensures a constructive catch protection of the intermediate sleeve.

The N-Eupex DK adds a double-cardanic variant to the already existing short andlong construction types. It is universally applicable, but it is particularly suitable for pump applications. With the introduction of the double-cardanic design, the selection of N-Eupex couplings can be adjusted even more specifically to the respective application.

At the same time, Flender achieved to increase the performance of the entire N-Eupex series by approximately 30 percent, and the bore capacity by up to 25 percent. The increased power density was achieved through extensive testing and material optimization. As a result, users benefit from higher torque, increased rotation speed and a change in size. The same performance can now be achieved with a smaller size.

With the so-called G-hub, the N-Eupex DK also receives a new, split hub design.The two half shells of the hub are bolted together. When the clamping screws are tightened, the half-shells center themselves over the feather key and position themselves correctly relative to each other. The feather key connection is therefore free of play. In addition, the service friendliness is increased. The coupled driving and driven machines do not have to be moved during assembly or disassembly ofthe coupling. This halves the time required compared to conventional hub design.

The N-Eupex DK is available in ten sizes for torques from 48 Nm to 2,300 Nm. The bore capacity of the hubs is suitable for shaft ends with diameters between 20 and 150 mm. The permissible speed for small diameters is 5,500 rpm, for large diameters 3,000 rpm. The N-Eupex DK can be used at ambient temperatures from -30 degrees Celsius to +80 degrees Celsius. It is ATEX certified and therefore suitable for use in potentially explosive atmospheres.

Source: Flender International GmbH