Ensuring the Right Chemistry at Honeywell: NETZSCH Rotary Lobe Pump Conveys Abrasive and Non-Abrasive Media

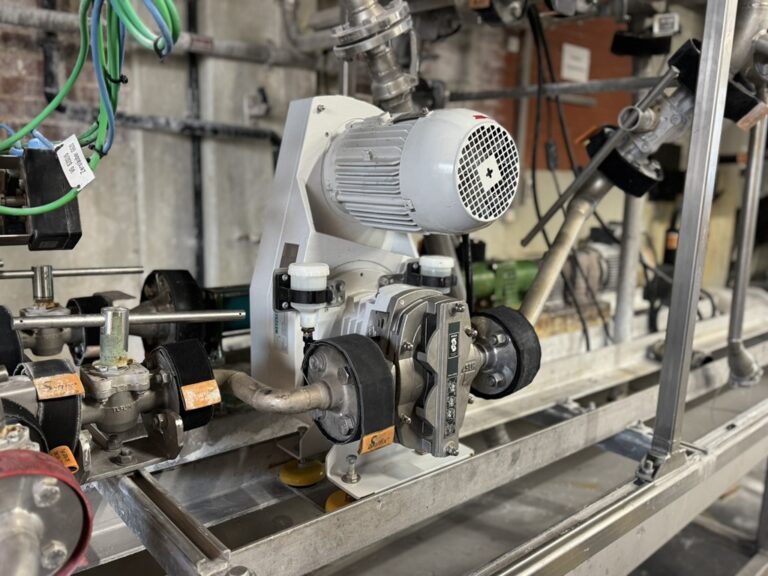

The lobes and mechanical seals of the TORNADO T.Proc rotary lobe pump are easy to replace. (Image source: NETZSCH Pumpen & Systeme GmbH)

Highly abrasive suspensions were as much to blame as rinsing cycles with deionised water. With a new TORNADO T.Proc rotary lobe pump from NETZSCH Pumps & Systems, the chemical producer could reduce production downtimes and ensure high-quality standards.

Fine chemicals are high-purity substances used for demanding electronics, pharmaceuticals, research applications, and speciality chemicals in other industries such as automotive, construction, and textiles. Honeywell produces more than 500 of these at its German site in Seelze. This diversity brings with it several challenges.

Plant downtimes despite redundant operation

Two older NETZSCH progressing cavity pumps, which the company had been using for over 40 years to convey suspensions and solutions, some highly abrasive, were also increasingly struggling with this problem. The system was cleaned with demineralised water between product runs, which is particularly aggressive towards metallic surfaces. Alternating cycles with abrasive and non-abrasive media and the intermediate rinsing cycles made it difficult to design the materials of the stator and the other pump components for the respective media - wear could hardly be prevented despite frequent changeovers. To reduce system downtime, the two units ran in redundant operation.

The suspension's highly abrasive properties meant that the pump's stator wore out particularly quickly and had to be replaced not only after the usual four-week product cycle but, in some cases, up to twice a day.

Production downtime and high maintenance costs

Unplanned system downtimes and production losses caused high costs. Thanks to the service and high availability of spare parts from NETZSCH, Honeywell Seelze could operate the two progressing cavity pumps reliably for many years. However, the chemicals manufacturer now saw the potential for improvement to reduce the time and costs of stocking components and maintaining the ageing pumps and decided to modernise them.

Process optimisation with NETZSCH

As a global specialist for customised pump solutions with more than seven decades of experience, NETZSCH develops and produces a wide range of pumping technology for complex applications and supports customers in all matters relating to design, maintenance and modernisation. To make production at Honeywell Seelze more resilient and to optimise internal processes given the demanding range of pumped media, a pump was required to convey all chemicals used on the system without prior changeover. The aim was to significantly reduce wear, even with highly abrasive media, and to change the affected components quickly and easily.

‘Based on these requirements, we recommended a TORNADO T.Proc rotary lobe pump in an all-metal design,’ explains Christian Eckert, Area Sales Manager at NETZSCH. ’The modern rotary lobe pump is particularly wear-resistant and easy to maintain.’ The reason for this is the practical FSIP design (Full-Service-in-Place), which enables complete CIP and SIP cleaning procedures and eliminates the need for time-consuming dismantling for service and repair work thanks to direct access to the pump chamber.

Customised solution with interchangeable lobes

With a pressure of 3.5 bar, the new TORNADO T.Proc at Honeywell Seelze conveys around 2.0 m³/h of media with a solids content of up to 32%. For most suspensions and solutions, as well as deionised water, NETZSCH chose lobes made of CrNiMo17-12-2 stainless steel, which is characterised by high corrosion resistance and strength. Only highly abrasive media could not be withstood for long. Special tungsten carbide-coated lobes are now explicitly used for this application. These reliably withstand a four-week production campaign.

During integration into the production process, the pump was initially opened several times and serviced as a precaution. Thanks to the FSIP design, Honeywell Seelze employees quickly became familiar with the maintenance work and could carry it out without long interruptions to production. The spatial separation of the pump and gearbox ensures maximum operational safety, even during maintenance.

‘Proven Excellence’ ensures the highest quality standards

‘The TORNADO T.Proc runs smoothly - regardless of the product being pumped. This saves time-consuming conversions and repairs. The old pump had to be converted every time the product was changed. This is now a thing of the past,’ says Christian Eckert, Area Sales Manager at NETZSCH. Thanks to the high availability of spare parts and the personalised service, procuring spare parts is also quick and uncomplicated.

Honeywell Seelze is planning to modernise another production plant with the TORNADO T.Proc rotary lobe pump to ensure its quality standards in the future.

Source: NETZSCH Pumpen & Systeme GmbH