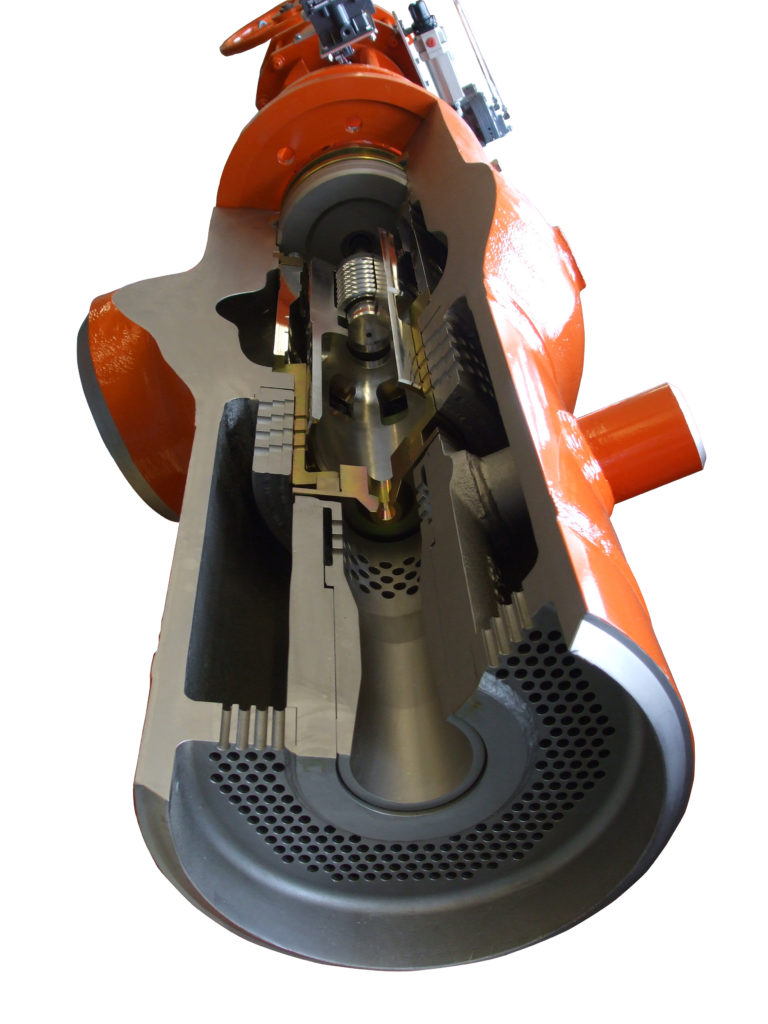

Direct Steam Conditioning Valves from Celeros Flow Technology

Copes-Vulcan Direct Steam Conditioning Valves (DSCV) from Celeros Flow Technology provide reliable, highly accurate control of steam in power generation, chemical processing, food processing and paper production. (Image source: Celeros Flow Technology)

Combining pressure and temperature reduction in a single unit, the Copes-Vulcan DSCV design is particularly suited to applications where valves typically remain closed for long periods of time to isolate steam flow. They are often deployed as the transition point for piping class and material.

Each DSCV is custom engineered to satisfy individual application performance criteria, using the considerable experience inherent in the Copes-Vulcan team. The angle style DSCV offers a high flow capacity to 9500 Cv. A forged pressure boundary design facilitates compatibility of the DSCV with steam and cooling water pipework. Pressure/temperature ratings up to ANSI Class 4500 are available as standard, with intermediate or split ratings provided as required.

The Copes-Vulcan DSCV is highly customisable, offering unlimited inlet/outlet connections and multiple spray configurations. There is also a broad range of actuators available to meet stroke time requirements. Trim options range from a balance plug through to multi-stage pressure profiling, including HUSH or Raven, for active noise attenuation. The Copes-Vulcan DSCV also features a diffuser for additional noise and vibration control. End connections can be welded or flanged.

Shutoff ratings up to ANSI/FCI 70-2 Class V are available. Depending on valve orientation and shutoff class, integral adjustable drain/ warming valves can be incorporated into the design.

The Copes-Vulcan DSCV is also designed to minimize downtime. Maintenance can be carried out with the valve body in line, since the trim is removable via the bolted or pressure seal bonnet. To optimize valve performance throughout the operational lifecycle, Copes-Vulcan offers customers a range of additional services, including start-up consultation, training on maintenance practices, field servicing, support with plant refurbishment and upgrading activities, identification of potential issues that could impact on operational efficiency, and decommissioning consultation.

Source: Celeros Flow Technology