Delicate and Quiet Operation with Alfa Laval’s new Robust Twin Screw Pump

Designed for handling fluids which are sensitive, abrasive, and either high or low viscosity, the Alfa Laval Twin Screw Pump is ideal for use in hygienic applications in the dairy, food and beverage, and personal care industries.

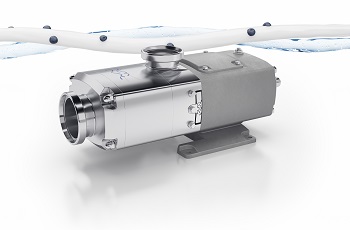

The Alfa Laval Twin Screw Pump is a positive displacement pump. As the pump rotates, the intermeshing of the two contra-rotating screws, along with the pump housing, form volumetric chambers. (Image: Alfa Laval)

"The Twin Screw Pump is the ideal choice for both high and low viscosity liquids, all pumped perfectly with complete reliability," says John Walker, Pump Portfolio Manager.

Additional benefits of the Alfa Laval Twin Screw Pump are that it is quiet and virtually pulse-free, as well as being smooth and gentle during operation. These characteristics make the pump an excellent choice for handling sensitive products.

Built on a robust, reliable platform that meets stringent hygienic standards, the pump is capable of handling both product transfer and Cleaning-in-Place (CIP). Its low pulsation characteristics and excellent solids handling capabilities reduce the risk of product damage, thereby improving product quality. Maintenance is simplified and process uptime increased.

Process flexibility

Two-in-one operation provides easy handling of process media of varying viscosities as well as CIP fluids. This simplifies piping and pump control, cutting costs and minimizing contamination risks. Superior suction performance with excellent lift capability and low NPSHR provides installation flexibility and increases product recovery.

Service and reliability

Quick, easy seal replacement with the pump in place is made possible, thanks to a cartridge seal with a truly front-loading, self-setting design. This maximizes process uptime and minimizes maintenance costs. An optional seal service kit program adds maintenance flexibility and cuts operating costs.

Operational safety

The Alfa Laval Twin Screw Pump features a clean, external stainless steel finish with profiled elastomers and mechanical seals fully surrounded by the product. Designed for maximum cleanability using FDA-conforming materials, the pump is both EHEDG- and 3-A certified. An optional ATEX version enables use in hazardous zones.

Source: ALFA LAVAL Corporate AB