Chemineer Spurs the Drinking Water Purification Industry With Coated Kenics UltraTab Mixer

Chemineer launched a static mixer called the Kenics UltraTab mixer that is having a positive impact on the Drinking Water Purification industry.

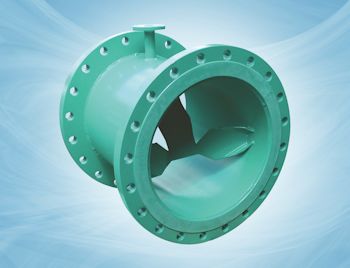

Chemineer™ NSF61 Coated Ultra Tab Static Mixer (Image: Chemineer)

The patent pending Kenics UltraTab mixer is designed for turbulent flow applications where a high degree of mixing is required in a compact space. The product is available in a variety of sizes and configurations to meet an extensive range of application requirements.

In turbulent flow mixing/blending applications, the UltraTab provides many performance benefits such as compact installation space, complete blending in short distances downstream of the mixer, and low pressure drop through the element. Low pressure drop through the UltraTab element enhances the energy efficiency of the process by saving pumping costs.

The UltraTab is designed to bring the additive into the water mixing stream directly before the mixing tab where the additive rapidly dilutes into the water stream. This design blends the additive as quickly and efficiently as possible with low pressure drop, resulting in a highly cost-effective solution to an age-old mixing application challenge.

The integral wall injector that is located upstream of the UltraTab mixing element forces the additive through the high energy dissipation region created by the mixing element, which provides superior mixing efficiency. This is a unique feature of the UltraTab design. Independent studies from the British Hydraulic Research Group (BHR) show that the UltraTab can produce a Coefficient of Variation (CoV), which is a measure of mixing degree, lower than 0.05 at a distance of three mixer diameters (3D) downstream from the mixer.

In the drinking water purification industry, engineers and operators do not have to compromise innovative mixing/blending technology to save space, which is always at a premium in any facility. The UltraTab mixer is short – very short and compact – which optimizes plant layout. The length of the Kenics UltraTab is less than one pipe diameter in many cases. That is all the space required. The flanged spool includes the additive port and the mixing tab or element.

An alternative between flanges insert (“sandwich design”) allows the mixer to be installed in existing straight pipe lengths of less than one pipe diameter.

When it comes to drinking water purification applications, most states now require that potable water equipment, such as static mixers, be coated with an NFS61 certified material. Chemineer uses a form of Scotchkote for its coating, which meets state requirements for NFS61 compliance. The Kenics UltraTab mixer features NSF61 certified coating on all process surfaces and is one of the only designs available in the marketplace today that will meet NFS61 requirements.

The Kenics UltraTab Mixer offers significant user benefits in these typical water treatment applications, where efficient mixing in a short length avoids costly overdosing and allows better control over the process by, for example, more accurate chlorine residual control, more efficient coagulation and shorter pH control loops:

- Mixing of pH adjustment chemicals in water

- general mixing of chemical additives into water

- Acid Dilution prior to injection

- Mixing Flocculation Agents into water

- Mixing coagulants into waterMixing Sodium Hypochlorite and chlorine solution into water

- Mixing Polymer solutions into water

The Kenics UltraTab mixer is having a positive impact on the Drinking Water Purification industry. The UltraTab provides many benefits such as compact installation space requirements, complete blending in short distances downstream of the mixer, low pressure drop through the element for energy efficiency, and an NSF61 certified coating on all process surfaces to meet state/industry requirements.

UltraTab mixers are also available in FRP and other alloys such as Duplex, Super Duplex and Hastelloy.

Source: NOV, Inc.