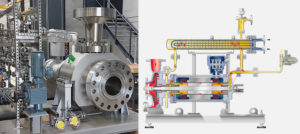

Canned Motor Pumps in Use at Petrochemical Plant in South-East Norway

Canned motor pumps in use at petrochemical plant in south-east Norway. (Image source: HERMETIC-Pumpen GmbH)

The supplied canned motor pumps, with “tandem” design, convey the medium [C3 fraction with propylene as main constituent] at a temperature of 22 °C. The differential head [H] is 379 m at a flow rate [Q] of 7.8 m³/h. The pump units are designed for a nominal pressure of 40 bar and have temperature- and level-monitoring features. For online monitoring of the hydraulic axial bearing, a rotor-position monitoring feature is also provided.

Thanks to the special tandem design of the multistage pumps, these machines are truly one-of-a-kind on the market. The unique arrangement of pumping stages results in minimal shaft deflection and load relief at the slide bearings. The “ZART” (Zero Axial and Radial Thrust) technology from HERMETIC ensures a contact- and wear-free running of the rotor unit.

As canned motor pumps generally contain no failure-prone components such as shaft seals, couplings and friction bearings, this technology is particularly suitable for extremely difficult operating conditions. The leakage-free pump design ensures the safe handling of hazardous and valuable products, while high availability and long service life time are characteristic features associated with it. Moreover, these hermetically-sealed pumps help to enable applicable environmental and work safety requirements to be met.

Previously, the plant owner had only used conventional centrifugal pumps with dynamic shaft seals in use. In light of the challenging service and the desire to increase system availability and minimise maintenance costs, the customer came to a realization that an alternative pump technology need to be adopted in order to meet the relevant requirements.

After a detailed evaluation of the possible solution, the customer opted for the canned motor pump. The decisive factors were the high level of safety offered by the sealless (and thus leakage-free) design along with the absence of wear parts and, consequently, longer maintenance intervals.

In operation canned motor pumps are convincing by easy installation and commissioning, compact footprint, quiet and vibration-free running and a comparatively small amount of instrumentation.

HERMETIC has been supplying canned motor pumps to the petrochemical industry for decades. Such pumps are used both in Greenfield projects and for replacement for problematic pump units in existing plants.

Standard models and customised pump solutions can be designed in compliance with the technical oil and gas directive API 685.

HERMETIC can provide reliable solutions for virtually any type of pump usage, from simple applications to the conveyance of conventional liquid gases and right through to cryogenic applications. Even extreme process parameter such as system pressures of 120 MPa and temperatures of 450 °C do not present any difficulties for the proven canned motor pump technology.

Source: Hermetic-Pumpen GmbH