Bungartz Special Pump Technology Proven and Repositioned

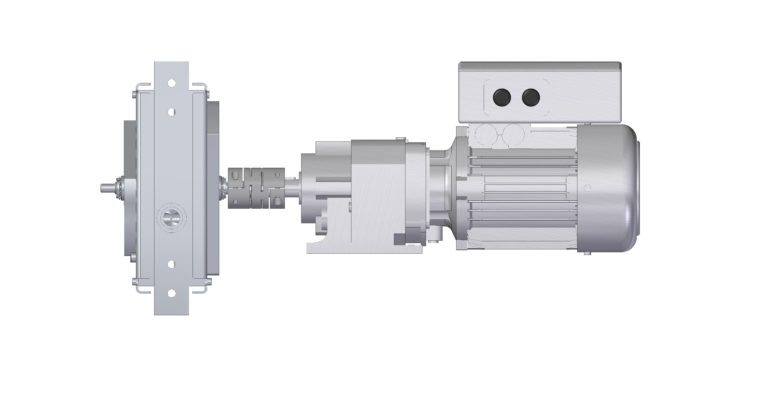

The new rotary piston pump with up to 1200 strokes per minute. (Image source: Paul Bungartz GmbH & Co. KG)

It is energy-efficient and (cleverly) combines the advantages of various already well-known technologies. At the same time, it is low in pulsation and - like some pumps from Bungartz - hermetically sealed. The novel design, in which the torque of the outer shaft is transmitted to the pistons by magnets, reduces the pump's maintenance requirements.

The fields of application of the new pump are numerous: The pumping of toxic, corrosive or viscous liquids is one of them. Shear-sensitive and explosive materials are conveyed just as safely as you have been used to with this manufacturer.

An innovation for the MOR / UMOR horizontal centrifugal pumps, which have been in production since the 1930s, will also be exhibited for the first time at ACHEMA 2022. In line with the credo of making good even better, Bungartz will be presenting the prototype of a completely revised centrifugally controlled standstill seal, which is intended to further minimize the inevitable small leakage during standstill in the future. Bungartz's robust and durable pumps are well known for their use in difficult applications, often for pumping media that are simultaneously hot, abrasive and corrosive. Primary shaft sealing as a hydrodynamic seal has also long been proven: Impeller back vanes keep the medium away from the shaft during operation, so no additional sealing is required during operation. Mostly used as slurry pumps, the MOR / UMOR types can be run dry and have a proven track record of very high availability, as they have no components subject to wear.

Source: Paul Bungartz GmbH & Co. KG