BBA: Manure Pump Saves Time and Money

Manure pump saves time and money. (Image source: BBA Pumps BV)

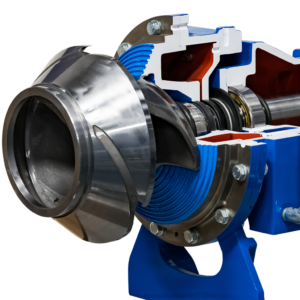

High head pump to cover the distance

The manure is pumped an incredible 5 km underground to service more than 500 hectares of arable land. Gerrit Peters, the agricultural specialist, selected the right centrifugal pump for the Smits family to cover this distance. An electrically driven BA-C100S26 pumps the digestate through its own underground piping system from the biogas plant to the manure containers on the surrounding arable land.

The benefits of the manure pump at a glance

- Time savings of up to 15 minutes per charge

- The spreading capacity is increased by up to 50 percent per day

- Three weeks fewer contract workers were hired

- Reduced tire wear

- Less environmental impact

- Short payback period

Electrically driven pump solution is better for the environment

In addition to saving time and money, this electrically driven pump solution also reduces CO₂ emissions. The centrifugal pumpset is packed in a lockable canopy and is supplied with its own green electricity from the biogas installation. Because the tractor is no longer required to drive from a field to the manure storage, the amount of fuel needed is significantly reduced.

Source: BBA Pumps BV