Baker Hughes Opens Eco-Centre Waste Management Facility

Baker Hughes opened its Eco-Centre waste management facility in Peterhead, Scotland, today, providing the North Sea oil and gas industry with the highest level of environmentally compliant waste processing services from the rigsite to final disposal.

The Eco-Centre facility can process in excess of 30,000 tonnes (33,000 tons) of drill cuttings and 14,000 cubic meters (3.7 million gallons) of liquid waste, or slops, annually.

For the first time, exploration and production (E&P) companies have a full-service facility to treat all of the liquid and solids waste generated during drilling operations. In addition, the Eco-Centre facility includes remote monitoring capabilities, allowing companies online access to track their waste streams and ensure environmental reporting compliance.

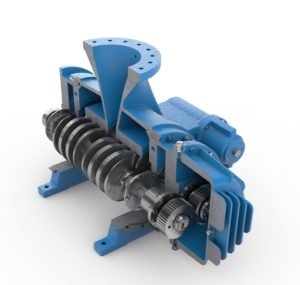

The Peterhead Eco-Centre – located north of Aberdeen – was developed in conjunction with local engineering and consulting firms, the Aberdeenshire Council, the Scottish Environmental Protection Agency and Scottish Water. The 30,000-square-foot Eco-Centre facility can process in excess of 30,000 tonnes (33,000 tons) of drill cuttings and 14,000 cubic meters (3.7 million gallons) of liquid waste, or slops, annually. The facility segregates each company’s drill cuttings, creating a transparent and fully auditable trail. The drill cuttings are processed to reduce oil content to less than 0.5 percent, allowing for disposal in approved landfills. Liquid waste is treated to separate and remove all solids and hydrocarbons, allowing the remaining liquid to meet or exceed the strict regulatory standards for reuse or disposal.

The Peterhead Eco-Centre facility also includes Baker Hughes’ Fluids Environmental Services (FES) Global Research and Development Center, serving as the primary R&D hub for emerging technologies designed to reduce the environmental impact of the oil and gas industry. In addition to drilling waste treatment technologies, the center will research drilling and production operations requiring a technology step-change to ensure the highest level of environmental stewardship.

Unlike other options in the industry, the Eco-Centre waste management facility provides E&P companies 24/7 visibility of their waste streams throughout the process. Baker Hughes’ Eco-Link online, remote monitoring software system was specifically designed for the Eco-Centre facility. In addition to providing full tracking and auditing capabilities, the Eco-Link software lets customers generate reports at any point during processing. The monitoring system means operators and regulatory agencies have a consolidated audit trail that readily demonstrates the complete accounting of a company’s waste.

The concept behind the Eco-Centre facility accounts for recycling and reusing the generated waste streams to reduce the overall carbon footprint of the facility and the operators it serves. Following processing, the “cleaned” solid materials are used in place of quarried aggregates to cap local landfill sites. The recovered oil is reused to fuel the processing mill at the center while recovered water is used to cool and rehydrate the recovered solids. To minimize use of local water resources, rainwater is captured and used for a variety of purposes, including fire suppression.

“The Peterhead Eco-Centre facility allows Baker Hughes to more efficiently meet the waste treatment and disposal requirements of offshore Europe operators,” notes Gary Rich, President of Baker Hughes in Europe. “This center is a flagship for technology innovation aimed at minimizing the environmental footprint of the petroleum industry – a critical business driver for Baker Hughes.”

The Peterhead Eco-Centre facility is the first purpose-built plant of its kind for Baker Hughes and serves as a model for future global Eco-Centre waste management services. Baker Hughes is currently engaged with E&P companies in other offshore areas to assess local environmental requirements and determine how the Eco-Centre waste management concept can be applied.

Source: Baker Hughes, a GE comany LLC