Aussie Pump Thinks For Itself

A new 3” trash pump designed to operate automatically has been released by Australian Pump Industries. The pump’s huge advantage is its ability to operate unattended!

Aussie’s Joe Attard with the Aussie QP3TI, an innovative driverless pump. (Image: Aussie)

Called the Aussie QP3TI, (with the “I” standing for “Intelligent”), the new pump is powered by Honda iGX Series engine. The engine offers both electric and recoil start.

It has a wide range of user friendly features that include auto stop/ start with float control and integrated ECU (Electric Control Unit) with a self-tuning regulator (STR) governor system. Through this unique ECU, located within the control box, the iGX Honda engine senses and adjusts the rpms to match the application’s load and speed requirements.

The automatic controls are complimented by a dashboard with manual dials that can control flow from low through to medium and high. These controls can adjust the discharge volume with a convenient pilot lamp and alert systems built into the programme.

The automatic standby operation of the pump allows auto engine on/off, auto engine standby and auto drain mode. An auto fill mode is also integrated in the system.

When the machine is set to auto drain operation the engine starts automatically and drains the tank or trench. It turns off as soon as the tank or trench reaches the low level required. The attached diagram illustrates how the float sensors work.

The float sensors can be set either at the suction or discharge point of the pump, allowing maximum flexibility.

Benefits to hire companies, contractors and even plumbers and drainers are obvious. The pump can run without the presence of an operator with the full knowledge that the units will work effectively in this mode.

The 3” trash pump delivers a flow of 1500 lpm with a maximum head of 30 metres. The suction lift is an astonishing 7.6 metres with fast priming being a part of the pump’s inherent design.

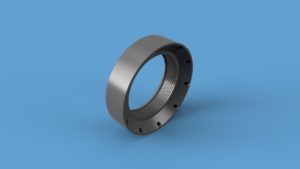

Like all Aussie trash pumps the new experimental QP3TI offers a big open style non-clog impeller, a silicon carbide mechanical seal and easy to open front port for pump clean out.

The machine comes as standard mounted in a full frame with wheels for ease of movement on site.

“This is our first venture with utilizing Honda’s iGX technology to add to it with additional features that make it more “pump friendly” said Aussie Pump’s Chief Engineer, John Hales.

“Apart from the automatic operation of the pump, and the ability to adjust flow and head in a pre-set manner we also have the big advantages of Honda iGX technology. That means fuel efficiency savings of up to 15% over conventional engines, smoother performance thanks to the ECU’s fine tuning of the throttle position and maintenance of precise engine speed, and lower vibration” said Hales.

“The engine also features an easy start auto choke to make life simpler for the operator” he said.

Australian Pump engineered the unit to be of real benefit to contractors, hire companies, plumbers and drainers.