API 685 Pump Is Ideal For Petrochem and Oil Industry Duty

A range of heavy duty canned motor pumps which is designed to be compliant with the American Petroleum Industry specification API 685 for sealless centrifugal pumps is now available through UK pump specialists Michael Smith Engineers.

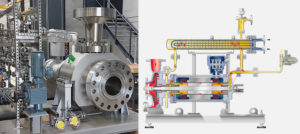

API 685 Pump (Photo: Michael Smith Engineers)

The Nikkiso-KSB API 685 canned motor centrifugal pump range is suited to applications in the petroleum, chemical, gas and oil refinery sectors and is ideal for transferring hydrocarbons, liquids with a low boiling point, liquefied gases, heat transfer media and also liquids containing solids. The pumps, which provide flow rates up to 360 m3/h and heads up to 220 metres, are designed for system pressures up to 40 bar and can withstand nozzle moments and forces four times higher than required by API 685.

The pumps have centreline supported casings and include wear rings located on the casing as well as the casing cover, helping to minimising maintenance costs. The pumps incorporate an automatic thrust balancing system which allows the bearing / thrust washer to function at minimised thrust loads over the entire usable capacity range to ensure optimum pumping performance. The Nikkiso KSB canned motor pumps come with an easy-to-read ‘E’ monitor with an LED display (local or remote), which indicates the axial and radial rotor position during pump operation alerting users to possible bearing wear and so helps to prevent motor stator damage or failure which can cause un-scheduled down time.

The Nikkiso-KSB API 685 canned motor centrifugal pump range are designed for mounting horizontally. A vertical configuration with in-line suction and discharge ports is also available. All the pumps offer secondary containment as standard

Source: Michael Smith Engineers