An Almost Everlasting Evaporator Circulation Pump

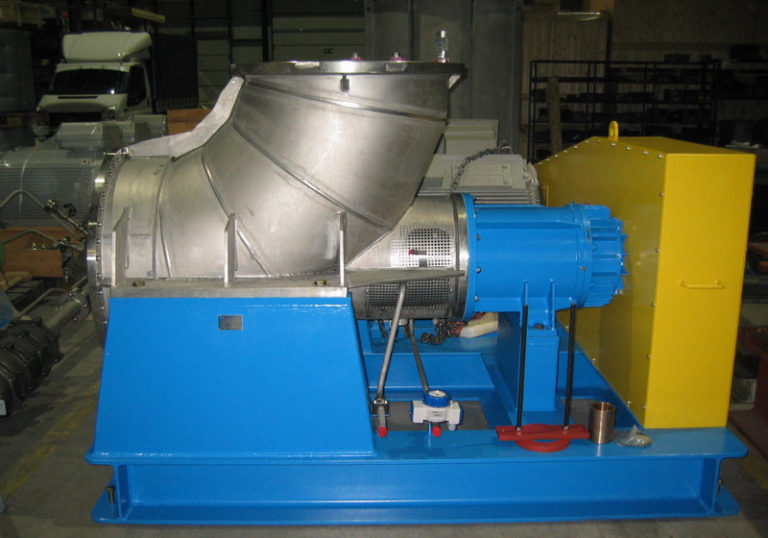

Evaporator circulation pump type CAHRM750K in the workshop prior to packing. (Image source: Sulzer Ltd.)

The challenge

The phosphoric acid is produced in a dihydrate (DH) process. The phosphate rock is attacked by phosphoric and sulfuric acid in a reactor. The 28% P2O5 acid produced is filtrated and then evaporated to a concentration of 54% P2O5.

The constraints of the evaporator circulator are:

- 54% P2O5 acid with contaminants (HF, H2SiF6, H2SO4,≈ 3% solids)

- maximum operating temperature of 95°C

- manufacturer standard design (high flow, low head and limited NPSHa)

- no speed variation

- heavy duty and nominal bearing duration > 25’000 hours of operation

The solution

Sulzer selected the best pump size and propeller design for optimum benefits to the customer:

- propeller specifically designed for the project, with high efficiency and lasting performance in a corrosive and erosive application

- optimal selection of the operating point with regard to the BEP and inherent hydraulic constraints of axial flow pump

- adapted mechanism for pulleys/belts assembly, guaranteeing perfect performance and long lifetime of the mechanical seals as well as trouble-free operation of the bearings

The construction material proposed by the engineering company was SS904L, which is a common material for such applications. Its advantageis good corrosion resistance in most low-temperature P2O5 applications.

Customer benefit

An axial flow pump with a state-of-the-art design, adequately selected to meet exact production needs and properly serviced, proved to be highly beneficial to our customer.

The pump was operated for eight years with no repairs needed. After that, the customer decided to replace the main wear parts: propeller, shaft, wear ring and mechanical seals.

Although many of the parts could have been re-used, the customer chose to replace them with genuine new parts. Reusing worn components would not have guaranteed a similar lifetime after restart.

Despite an apparently low solids content in the fluid, the total weight of solids passing through the pump during one hour of operation can be estimated to be about 180 tons. These solids are mainly gypsum and precipitates. The traces of erosion visible on the propeller did not reveal abnormal patterns. The hydraulic design tailored for the project turned out to be successful and highly reliable.

During these eight years, the total cost of ownership (TCO) was kept to a minimum, with no added costs for commissioning, no down-time costs, no removal and disposal costs. The only costs incurred were related to operation, i.e. energy and consumables, and routine maintenance.

"The Sulzer axial flow pump type CAHRM750K we use in the evaporator circulation loop has been running perfectly since start-up and we are very satisfied. We only had to replace some parts after eight years of operation, which is remarkable." Eng. Yasser Ahmed, Production Manager at NCIC

Project data

The pump is installed in an evaporation / concentration loop. It is located between the evaporator and the heat exchanger and takes care of the continuous circulation of the phosphoric acid through the heat exchanger and the evaporator.

| Item | Description |

|---|---|

| Application | Evaporator circulation pump |

| Liquid | 54% phosphoric acid @ 86°C |

| Pump type | CAHRM750K |

| Construction material | Casing/wearing/shaft in WN 1.4539 Propeller in WN 1.4584 |

| Nominal speed | 520 (rpm) |

| Lubrication | Grease |

| Installation | Pump/motor side mounting on common baseplate |

| Motor | SIEMENS 250 kW – 3’300 V - 50 Hz |

| Transmission | Pulleys/belts (10 belts) |

| Mechanical seals | John Crane P32+FA33 |

Source: Sulzer Ltd.