Air-Operated Double-Diaphragm Pumps Set The Standard In Adhesive-Backing Applications

Wilden announced that its Original Series T2 Metal Air-Operated Double-Diaphragm Pumps feature the performance versatility necessary for use in adhesive-backing applications, such as the attachment of a poluene coating to paper products.

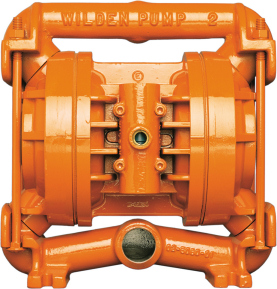

T2 Metal Air-Operated Double-Diaphragm Pumps (Wilden)

This 25 mm (1”) pump has wetted housings, water chambers and manifolds that are constructed of aluminum and is available with PTFE elastomers, making it ideal for the safe and efficient handling of adhesive backing. The pump offers flow rates to 132 lpm (35 gpm) and can handle pressures up to 8.6 bar (125 psi). It has maximum suction-lift capabilities of 5.18 m (17’) for dry products and 9.45 m (31’) for wet products, while being able to handle solids with diameters reaching 3 mm (1/8”). Elastomer options include Buna-N® and Neoprene.

Wilden’s T2 Series pumps are equipped with its Turbo-Flo™ air distribution system (ADS). This ADS operates on differential pressure only, meaning there are no mechanical trip rods, bearings or springs that can wear and need repair. It has an externally serviceable air-valve body that is attached to the center block. Built-in air-valve tolerances allow for the passage of some moisture and air-line particulates, allowing free movement of the air valve.

Source: Wilden