Adaptive Docking System for Engine Testing by Reich-Kupplungen

More productivity, reduced rigging times, less operating costs. The new docking system from Reich-Kupplungen helps automate the process of changing the test objects for combustion engine testing to the greatest possible extent and thus enables a significant increase in the efficiency of engine test bench operations.

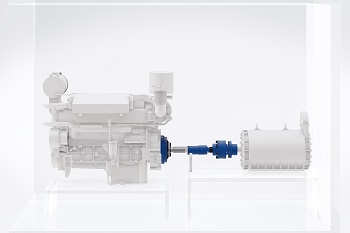

Self-centering feature – no manual centering required. (Image: Reich-Kupplungen)

The adaptive docking system was showcased for the first time at the this year s Automotive Testing Expo Europe in Stuttgart. The trade visitors, and especially the vehicle manufacturers and component suppliers, were particularly impressed with the self-docking and self-centering fixture. It consists of two standard components - a transverse pin and a sleeve which are both straight-toothed. Rigging only involves the mounting of the matching coupling with the pin to the engine. Given that this work is performed outside the test bench area, the rigging times are minimised in the test cell.

Rigging additional engines while testing

"This fixture allows for preparing other engines to be tested while one engine still undergoes testing. There is no longer need for complex mechanics and manual intervention on the dynamometer side“, explains Ulrich Bentele, Sales Manager at Reich-Kupplungen.

The basis is a correctly positioned, solid support on which a CV-jointed sleeve is placed. While the engine with the mounted coupling and the toothed pin is approaching its destination, the sleeve is lifted by up to 15 mm and turned until the toothed components come into mesh. All toothed shaft components come into mesh in any turning position while maintaining a good balance condition. The new modular construction-based docking system is designed for rotational speeds up to 6,000 rpm.

TOK coupling system

Coupling shafts and highly flexible couplings of Reich-Kupplungen make are designed to match a great variety of combustion engines. Rated for rotational speeds up to 10,000 rpm and equipped with a high torsional flexibility and torque transmission capacity from 100 – 70,000 Nm, they are perfectly suited for demanding test bench applications.