New BA150KS DriveOn has the Lowest Life Cycle Costs

(Image source: BBA Pumps BV)

Never before has sewer bypass pumping been this sustainable and cost effective.

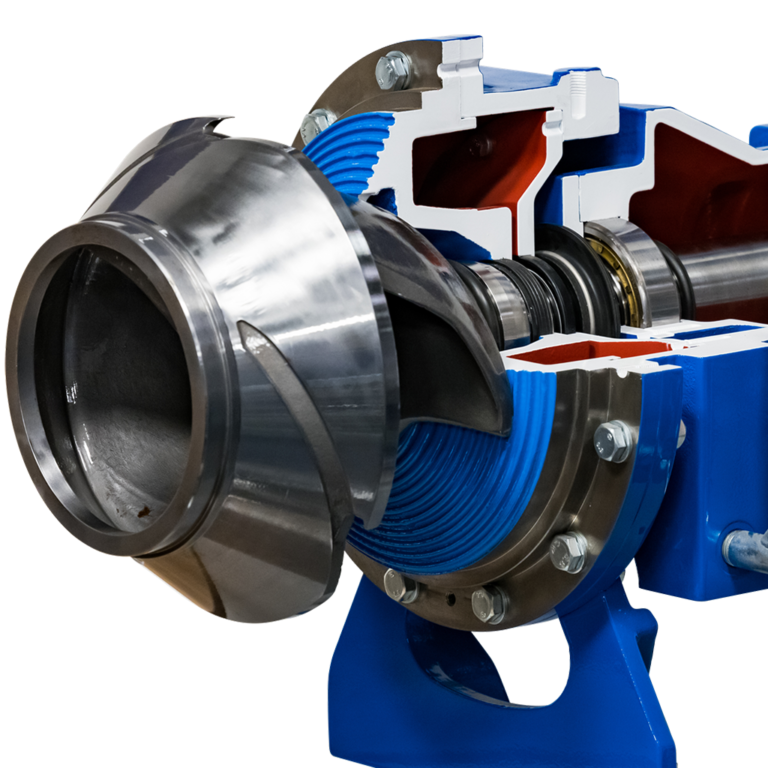

The Pump

The BA150KS is a centrifugal pump with a screw channel impeller for pumping raw sewage. Long fibrous materials and coarse dirt particles are simply devoured. Liquids are quickly primed by its inbuilt vacuum system and the sewage pump performs like a real 6-inch:

- Maximum flow 400 m³/h

- Head up to 27 mwc

- Excellent NPSHr curve

- 100 mm solids handling

- Specification data sheet

The Engine

No aftertreatment system

The pump is driven by an electronically controlled atmospheric engine. Emission levels are so low that the engine is stage V certified, without the use of after-treatment systems. Therefore, we are going to pump fluids again without a turbocharger, without an EGR valve and without a particulate filter!

With DriveOn technology

The well-known BBA Pumps DriveOn concept stands for extended maintenance intervals of 1500 running hours. This results in a 66% reduction in required maintenance on the pump and engine; lower oil, filter and labour costs and minimal pump fleet downtime.

Lowest Life Cycle Cost calculation

The Life Cycle Cost method visualizes the costs incurred during the life cycle of a product. For diesel driven pumps, the purchase price represents a relatively small part of the LCC. The larger part of the total costs goes to fuel consumption and maintenance. Below you will find the savings in percentages compared to the existing model BA150KS D285 with 3H50TICD.

BA150KS DriveOn price improved by 8%

An engine without a turbocharger and aftertreatment system not only simplifies your work, with fewer components required the price of the pumpset can be reduced by 8%.

BA150KS DriveOn 30% less fuel consumption

The engine delivers enough power to perform at 1700 rpm as a full-fledged 6-inch sewage pump. With a specific fuel consumption of 235 g/kWh, the calculation comes to a maximum of 5,5 liters/hour. This makes the pumpset more than 30% more favourable in terms of fuel consumption.

BA150KS DriveOn 66% less maintenance

With no particulate filter to clean or regenerate, no stuck EGR valve or broken turbocharger, maintenance work and all associated costs are greatly reduced. However, it’s the DriveOn technology itself which provides the greatest savings. Instead of servicing the pumpset every 500 operating hours, we can now extend this to 1500 running hours. From now on your pump can operate with 66% less maintenance.

Additional BA150KS DriveOn benefits

The engine can operate even with high sulphur content fuel (maximum 5000 ppm.) This gives a unique advantage, avoiding potential costs that could arise through engine damage.

As an additional option the automatic level control can be regulated by an optional pressure sensor. This means that the pump not only switches on/off at high and low fluid levels, the electronic motor will also automatically regulate the speed at a specified target point.

The noise level is kept extremely low due to the low engine speed combined with the super silent canopy.

Combustion engines that run on fossil fuels emit approximately 2600 grams of CO₂ per liter of diesel. However, this pumpset consumes approximately 30% less fuel and therefore emits 8 kg less CO₂ per hour!

Source: BBA Pumps BV