Vesconite Labyrinth Seal Improves Desalination Pump Performance

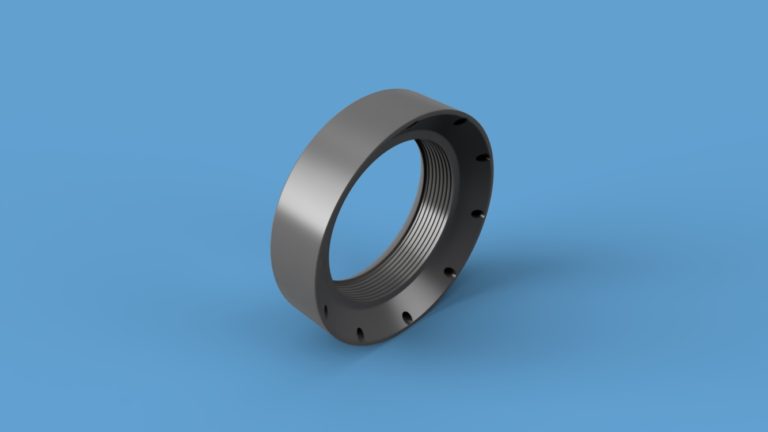

A labyrinth seal that Vesconite Bearings produces. (Image source: Vesconite Bearings)

His company advertises that “thanks to today’s state-of-the-art technologies, potable water and desalination plants are able to achieve levels of safety and efficiency that were previously unimaginable”, and these are some of the considerations that he uses when he develops products for this industry.

It was initially for efficiency reasons that the pump OEM engaged with Vesconite. Wear rings and seals, such as those produced by Vesconite Bearings, exhibit 5% efficiency gains, the product manager says. With high power intensities, the savings from these gains become increasingly important and have resulted in the whole world striving for more efficiency in the technologies that they employ, he notes.

Interestingly, the technology company believes that Vesconite Bearings’ main differentiating factors are its service and its flexibility. The product manager informs that a competitor had in one case quoted a seven-to-12 week delivery time from the placement of an order, as compared to a week’s despatch time for Vesconite. “Sometimes a lengthy delivery time is not acceptable for us,” he says.

Vesconite’s service and support was also a distinguishing factor in choosing labyrinth seals made from Vesconite self-lubricating no-swell bearing materials. The product manager explains that Vesconite Bearings was willing to discuss the technology company’s design requirements and did not simply dismiss them as impossible to achieve.

As a result, the labyrinth seal was produced applying the close clearances that the client desired. “We were able to search for solutions together,” describes the product manager. The technology company has been using Vesconite parts for five years and estimates that between 40 and 60 pumps globally have between 80 and 100 Vesconite parts installed on them. These are used in a variety of industries, including desalination, which is becoming an important way to secure drinking water for urban needs.

Source: Vesconite Bearings