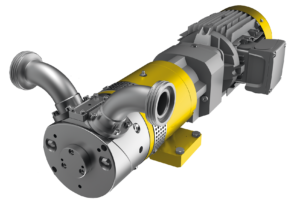

New Sinusoidal Pump for Shear Sensitive, Viscous Pharmaceutical Products

The new sinusoidal Certa Plus tecnology offers pharmaceutical manufacturers lower shear, lower power consumption, full traceability, and ultimate cleanability. (Image source: Watson-Marlow Fluid Technology Group)

Certa Plus utilises MasoSine’s considerable experience in sinusoidal pumping technology to meet a broad range of applications. An innovative advancement over conventional lobe pumps, the new sinusoidal Certa Plus tecnology offers pharmaceutical manufacturers lower shear, lower power consumption, full traceability, and ultimate cleanability when transferring syrups, oils, creams and gels.

Manufacturing pharmaceuticals presents a range of complex challenges to ensure the medicine is high-quality and free from contamination. Certa Plus was developed to guarantee cleanliness, with added capabilities that assure quality across a wide range of pharmaceutical products. The efficient design of the pump not only reduces cleaning time but also saves electricity, minimising cost and carbon footprint.

Protect product quality

Maintaining the quality of high-value products with a broad range of profiles is essential for the pharmaceutical industry. Certa Plus provides virtually pulsation free product flow with no need for ancillary dampeners. This improves both flow meter accuracy and heat exchanger efficiency. The low shear handling minimises the temperature increase of the pumped liquid as well as improving batch consistency and final product quality.

Versatile, robust fluid handling

Certa Plus is capable of transferring and handling a wide range of challenging products from syrups and sugar solutions to lozenge products. Its continuous flow and high suction support the efficient manufacture of pastille products. Syrup and sugar solutions can also be processed with ease as the seal flush reduces the risk of sugar-based products drying out at the seal.

Across pharmaceutical applications, varying temperatures result in products with varying viscosities. For example, in the production of suppositories, pumping at lower temperature means an increasing viscosity of the product. The powerful suction of the Certa Plus handles both low viscous liquids such as oils, and high viscous products, such as creams and gels, with ease.

Clean and efficient technology

The pump is rigorously tested to comply with the most up-to-date regulations required for the pharmaceutical industry. Clean in place (CIP) capabilities enable ease of cleaning and allow the pump to be easily integrated into an aseptic fluid path. The pump can then be wet cleaned without dismantling and is steam sterilisable and bacteria-tight to remove the risk of residuals and contamination. Certa Plus has full aseptic certification (EHEDG Type EL Class I and EHEDG Type EL Aseptic Class I) and all components are made of FDA and USP Class VI certified raw materials.

The unrivalled sanitary design reduces the amount of cleaning chemicals used and cuts the required cleaning cycle time to a minimum, improving process efficiency. The pump also offers an energy efficient alternative, requiring up to 50 percent less power than lobe or circumferential piston pumps, greatly reducing electricity use and hence carbon footprint.